Wisconsin-based Processed Metal Innovators (PMI) is a metal fabricator that produces stamped and welded metal parts in sizes ranging from a few inches to 10 feet using thin-gauge to three-quarter-inch and heavier materials. Facing a shortage of certified welders and with traditional welding robots unable to handle high mix/low volume runs, PMI turned to collaborative welding automation from Hirebotics to increase productivity and profitability.

Erik Larson, VP of operations at PMI, was tired of turning business away due to labor shortages. “There’s been a lot of business that’s come knocking on our door,” he explains, “and a lot of it in the past we’ve had to no-bid because it requires welding. We only have about seven welders and for some of these jobs, we needed nine or ten welders. Right now, we have enough quotes out there that we would have to have hired 30 more welders.” With traditional robotic welders not feasible for small runs, Larson needed another option.

PMI had experience with Universal Robots’ collaborative robots (or ‘cobots’) following a successful two cobot deployment on mechanical press tending tasks. The deployment was led by Nashville, TN-based Hirebotics, a UR Certified Systems Integrator and pioneer in cloud-connected cobot systems and specialized collaborative welding solutions.

PMI also had experience with traditional welding robots, which turned out to be unsuited to high mix/low volume production, given that they require tooling fixtures that can take up to 16 weeks to be built. Especially for small-run parts, traditional robots and fixtures simply weren’t cost-effective.

So, when Larson discovered that Hirebotics offered a complete out of the box, robot welding system that includes a cobot from Universal Robots, the pieces immediately clicked into place.

“They are collaborative robots and you don’t need a large guarding system around them. They’re very small, easy to use, very easy to program. It’s a win-win package—it’s the future for doing small welds,” says Larson.

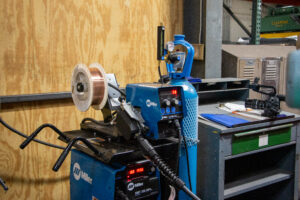

Collaborative welding robot with easy-to-use software

Designed for easy implementation and programming, to use Hirebotics’ cobot-powered welder human welders simply teach it welds via an intuitive Hirebotics app that will run on any smartphone or tablet. A library of pre-installed welding programs further streamlines the deployment process.

“The Hirebotics team came in […] and within two hours they had it set up. Within half an hour, I was running it and programming it and doing it all by myself,” says Shaun Bruce, PMI’s robotics and automation area lead. “I’m not a certified welder, but I’m able to easily just load a program, and I’ve got my tables mapped out in pictures, so I know where to put my tooling and my jig system, and I’m able to swap between parts within a matter of fifteen minutes,” he says.

Half the cost of manual welding

“Compared to what an employee would get for their hourly wage, plus all their overhead costs, you’re probably saving half of what you would pay a normal welder,” says PMI’s Larson. “We can go out there and quote work we haven’t been able to quote before because we know by the time we accept the PO, we can get a robot in here and ready to weld the parts before we even get the first order in the door.”

Cost-effective fixturing and easy maintenance

Cost-effective fixturing and easy maintenance

Once PMI fixtures a part, Larson explains, “You have a little diagram of it and every time you go to put that program back in, you can set your part up the same as you did before, so it doesn’t take a large or expensive fixture to do it. It’s just plug-and-play.”

It can take two weeks or longer for a service technician or engineer to fix issues with traditional welding robots. By contrast, HireBotics collaborative welding robot system includes a 24-hour service that responds to the touch of a button in the Hirebotics application.

“If I have any kinds of issues, I can message Hirebotics on this app and instantly get a reply back. It’s not hours of waiting, days of waiting; it’s seconds sometimes and for troubleshooting real-time, the problem is resolved within minutes,” explains PMI’s Bruce.

Manpower now available for larger, more profitable welds

As in every weld shop, the profit margin on larger weldments is significantly bigger than on small welds. PMI’s new cobot welder enables the company to reallocate manual welders to handle larger parts, while still getting the smaller welds completed, says Larson: “We’re not replacing anybody in our company with robots; we’re just moving people around to where they add the most value.”

As in every weld shop, the profit margin on larger weldments is significantly bigger than on small welds. PMI’s new cobot welder enables the company to reallocate manual welders to handle larger parts, while still getting the smaller welds completed, says Larson: “We’re not replacing anybody in our company with robots; we’re just moving people around to where they add the most value.”

Larson has also found that the robots appeal to younger workers, who are often hard to attract to manufacturing jobs: “We found out when we put these robots in and we were looking for a position to be the robotic and technology lead person that we had a lot of younger employees all interested in applying for that position because they like their phones and they like computers. It’s a big hit for the younger generation who wants to be into tech to be able to work and program robots.”

Proving that cobots can weld

Young people may gravitate towards using collaborative robots for welding, but the industry took some convincing, says Hirebotics’ Rob Goldiez. “Most people who have been around the industry for a long time believe welding—which is a heavy-duty task—is best suited for traditional robots. They don’t think that a collaborative robot is up to the task. And it’s not just the motion of laying down a bead. This is the robot laying down a weld and then cutting it and analyzing it and x-raying it to make sure that it meets the standards that they would expect and want to present to their customer base.”

Young people may gravitate towards using collaborative robots for welding, but the industry took some convincing, says Hirebotics’ Rob Goldiez. “Most people who have been around the industry for a long time believe welding—which is a heavy-duty task—is best suited for traditional robots. They don’t think that a collaborative robot is up to the task. And it’s not just the motion of laying down a bead. This is the robot laying down a weld and then cutting it and analyzing it and x-raying it to make sure that it meets the standards that they would expect and want to present to their customer base.”

Hirebotics is also able to rapidly incorporate customer feedback. While early versions provided basic welds such as straight lines, stitch welds, and tack welds, user feedback from early customers such as PMI prompted Hirebotics to rapidly develop more sophisticated processes, including multi-segment and radial welds.

That expertise now yields concrete results, including consistency that even manual welders can’t meet. PMI’s Larson says, “The quality of the welds is great because you program a weld to be in that specific spot, the weld’s going to be in that specific spot. If you program it to be two inches on that seam, no matter who runs that program or who sets the part up, it’s going to be every two inches on that seam.” That’s not necessarily the case with human welders, adds Larson. “You go back to the traditional hand welder, well, they’re not sure how much two inches is—it might be an inch and a quarter, it might be an inch and a half, it might be a two-inch gap or a two-and-a-half-inch gap. So it really takes the guesswork out of making sure you lay the weld down in the right spot.”

About Hirebotics

Founded in 2015, Hirebotics is a cobot technology developer headquartered in Nashville, Tennessee. Hirebotics designs and develops tools designed to improve the productivity, usability, and affordability of collaborative robot systems. Hirebotics entered the welding automation space as a key collaborator in the development of the popular BotX cobot welding system. In 2020, Hirebotics launched Beacon, a powerful free platform with cobot application building, remote cobot monitoring and maintenance, and 24/7 global support functionality. In 2021, Hirebotics launched Cobot Welder, Powered by Beacon; a complete software and hardware package for collaborative welding deployments.

www.hirebotics.com