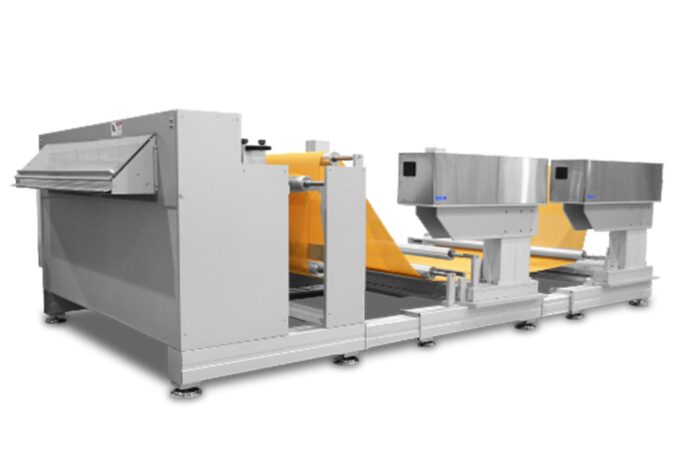

Like all AZCO cutting assemblies, the SUR SIZETM Sheeter FGW 1650 has a modular, “building block” approach that supports additional features to meet specific operational needs. For example, we can seamlessly integrate unwinds, rewinds, sensors, light towers, rollers, eye registration, web-guiding systems, tray lifts, conveyors and more.

Additional features and technical specifications include:

-Maximum cut width: 1,650 mm.

-Servo motor drive system.

-Tolerance: +/- 0.38 mm or +/- 0.1% — whichever is larger.

-Power requirements: 110 V AC or 220 V AC.

-Compressed air requirements: 30 to 90 psi.

-A no-product sensor.

-Color touchscreen, facilitating setup and monitoring.

About AZCO

AZCO Corporation is an ISO 9001 Certified company established in 1983. We design and manufacture simple and reliable modules and units used to feed, cut and place products. This concept is based on a building block model. Standard modules can be purchased alone or in combination to provide a solution that meets your unique needs, at a competitive price and with quicker delivery. Seamlessly integrating our units into an existing line increases your production speed and reduces downtime, saving you time and money.