Reflecting the different needs of larger industrial customers and small- to medium-sized fabricators, ESAB’s FABTECH 2024 exhibit will have two prominent areas dedicated to these customers and their unique needs. FABTECH 2024 runs from October 15 – 17 in Orlando, Fla., and ESAB will exhibit in booth W3801 at the entrance to the West Building.

“We are excited to mark ESAB’s 120th anniversary while showcasing the bredth of our advanced portfolio,” said Eleanor Lukens, President of the America’s, ESAB. “From the company that invented the first coated welding electrode, to a global premier industrial fabrication company with portfolios to address the demands of fabricators large and small, ESAB has been a proud contributor to the fabrication industry for more than 120 years. We are excited to welcome customers to our booth again this year and work with them to take productivity, cost savings and quality to the next level.”

Products for Industrial Customers

One portion of the booth focuses on technologies that improve productivity, workflow and business results for industrial companies, including:

- Live arc demonstrations include the Red Dot award-winning Warrior® Edge 500DX/RobustFeed Edge DX and its SPEED, PULSE, THIN and ROOT weld modes that deliver faster travel speeds, reduce heat input, increase puddle control and decrease spatter.

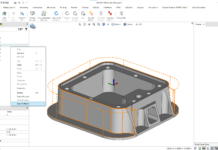

- The ESAB Cobot and an industrial robot with the new RoboFeed Edge robotic wire feeder, the new Aristo® Edge 500R power source, an automation gateway, a variety of torch options and dress kits for leading robotic systems.

- The new InduSuite FloCloud system, which enables industry to track gas process parameters, analyze gas consumption and identify gas leaks and over consumption.

- The WeldCloud suite of software applications to analyze and document welding productivity metrics, manage fleets and simplify traceability and compliance with connected welding systems.

- ESAB filler metals including the enhanced AlcoTec 4000 series wires with smoother feeding performance and fewer tangles, as well as the new OK Autrod 42 LSW low-slag 70-S solid wire.

- Automated welding systems in the booth include AMI® orbital TIG systems, the Versotrac tractor, an industrial robotic cell, and ESAB’s industry-leading integrated SAW systems with new Adaptio AI-driven wire placement technology, the Aristo® 1000 AC/DC power source, SAW filler metals and fluxes, and CaB column and booms.

- Cutting automation systems on display include the ESAB Combirex™ PRO and the highly affordable Thermal Dynamics® Automation Precision 130 plasma power source.

Products for Small- and Medium-Sized Businesses

The second half of the ESAB exhibit will engage small- and medium-sized fabricators and the next generation of welders with technology such as the award-winning Renegade™ VOLT ES 200i battery-powered welder, named to Popular Mechanic’s Tool of the Year list. The ESAB Cobot, which features an easy-to-use programming application, empowers welders, not programmers, to automate applications, bid more competitively and win new business. Cutting automation systems such as Swift-Cut Pro enable even the smallest company to leverage the power of CNC technology, bring metal cutting in-house, expand service offerings and improve delivery times.

New products this year at the show include the Rebel™ EMP 215ic (now enhanced with pulsed DC TIG capabilities), the more powerful Thermal Dynamics Cutmaster™ 50+ and 70+ manual plasma cutters, and the new Savage A50 LUX helmet with a flawless EN 1/1/1/1 optical level. The ESAB Rogue series of Stick, TIG and welders are also featured.

ESAB is pleased to offer even more hands-on use, skills contests using Victor® torches and regulators, promotional drawings, and other activities to mark the company’s 120th anniversary.