L&L Special Furnace company recently delivered a large floor-standing box furnace to the heat-treating department of an investment castings supplier. The furnace will be used as support in the customer’s tool and die production along with tempering of finished castings.

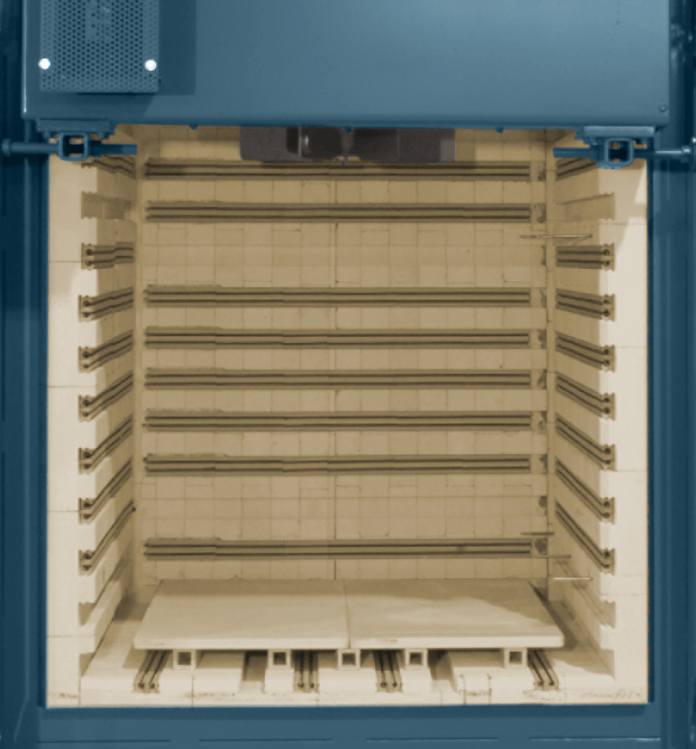

The L&L model XLE3436 box furnace has an effective work zone of 34” wide by 22” high by 32” deep. It is equipped with a direct-lift vertical door with a floor switch to activate. The cantilevered vertical door eliminates the need for the upright structure to reduce the overall height of the equipment.

The furnace includes a program control and overtemperature protection. A four-zone SSR control with digital biasing is provided to balance temperature gradients. The XLE3436 also features a paperless chart recorder with six thermocouple inputs, a heavy-duty Inconel sheathed thermocouple, a recirculation fan, and an atmosphere-sealed case for deployment with inert atmospheres.

The inert blanketing gas enables the part to be heat-treated with minimal surface de-carb. A stack light indicates the furnace status via an audible and visual indicator light mounted on top of the control.

Additionally, the furnace is equipped with a pyrometry package that has reference control thermocouple ports along with corner locations to record the high and low points within the unit as indicated by the latest temperature uniformity survey.

All L&L models can be designed with various options and be specifically tailored to meet your thermal needs. The company also offers furnaces outfitted with pyrometry packages to meet ASM2750.

Options include a variety of control and recorder configurations. A three-day, all-inclusive startup service is provided with each system within the continental US and Canada. International startup and training service is available by factory quote.

If precise temperature control and uniformity is key to your process, then L&L is a great choice.