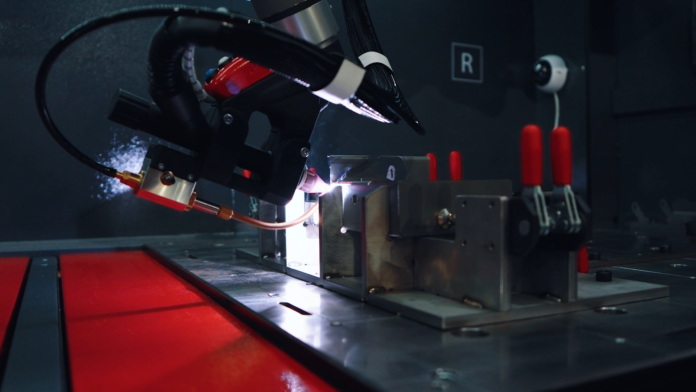

Automation is the word in manufacturing today, and Cincinnati Incorporated is continuing its tradition of innovation with the introduction of the industry’s newest welding technology. Simple to use and easy to program, the CINCINNATI Cobotic 100T Welding Cell is the first of its kind for TIG welding.

With a working range of 2400 mm x 1200 mm (approx. 4’ x 8’) the automated system is suitable for large or small production batches. The cell is compact, easily repositioned, and contains advanced safety devices including continuous robot elbow monitoring.

Cincinnati’s Ryan Lemmel, Business Unit Leader, Aftersales, explains that the system offers advanced automation and features that make the system powerful yet easy to operate while measurably impacting the bottom line.

“With a touchscreen control interface and intuitive programming buttons, processes are quick and simple,”

“With a touchscreen control interface and intuitive programming buttons, processes are quick and simple,”

said Lemmel.

“We’ve eliminated complicated off-line programming allowing the robot to be programmed using a tablet and buttons on the torch. The 100T autonomously detects sheet metal deformation without operator intervention. Automating the welding process maximizes limited resources and advances productivity by allowing shop floor personnel to be allocated away from welding operations.

Additional features include:

Additional features include:

- A dual work zones allow operators to weld in one zone while safely unloading parts in the other

- Use of UR5e collaborative robot with 6 axes and 6 rotating Degrees of Freedom (DoF) joints with +0.03mm (0.001 in) precision

- Additional 7th axis 1800 mm (5.9’), designed to add flexibility and maximize the reach of the Cobot arm.