To sustain growth and profitability in a competitive market, a company must be receptive to innovation in all forms. In recent years, the volatility of the custom machine building market has proven to challenge many growing companies. However, one custom machine builder has learned how to thrive in such an environment.

ABCO Automation Inc. in Greensboro, North Carolina, has consistently decreased costs and increased profits by constantly looking for new opportunities to source custom components used in machine builds.

ABCO Automation, Inc. is not a typical custom machine builder because the company builds machines for a vast number of industries as opposed to a single focus on a few select industries. “We have an extremely diversified customer base, which is crucial to our success,” explains Brad Kemmerer, the President of ABCO Automation. Kemmerer noted that by servicing customers from a variety of industries, ABCO is less susceptible to economic fluctuations that may impact any single industry. “If an industry goes into an economic slump this does not affect ABCO because we have a diversified customer portfolio covering many industries,” noted Kemmerer. ABCO is well positioned to face competition within industries with this diversified business model.

As Kemmerer further elaborates, “The other side to a diversified customer portfolio is that you face a lot of competition, which puts a lot of cost, time, and performance pressures on us.” This creates an environment where ABCO must rely heavily on continual innovation if it is to remain competitive in the extremely dynamic custom machine building market.

Competition and sustainable growth in such a market requires that ABCO develop long term, mutually beneficial relationships with customers. To this end, ABCO is committed to providing customers with a single source for innovative solutions, automation services, and manufacturing support. ABCO has found these to be key contributors to programmatic success; the company prides itself on exceeding expectations for quality, execution, and service in all customer interactions. Kemmerer explains, “In this business we see competitors come and go all the time so it’s either you dedicate yourself to your customers and put them first or you simply disappear.”

The search for a cost-effective component solution

ABCO is constantly searching for new sourcing methods for the custom components it uses in projects with the goal of reducing the total quantity of custom components that are employed in machine builds — including a more cost-effective source for machined linear shafts.

ABCO is constantly searching for new sourcing methods for the custom components it uses in projects with the goal of reducing the total quantity of custom components that are employed in machine builds — including a more cost-effective source for machined linear shafts.

The procurement process for usable machined shafts entailed first purchasing blank linear shafts from a distributor and then machining the shafts using the internal machine shop resources at ABCO. This process was quite costly for ABCO, and in looking for ways to save resources, the company reached out to MISUMI and discovered configurable linear shafts with the ability to specify length, diameter, shaft end style, material and surface treatment.

Furthermore, drawings are not required because ABCO engineers can use the MISUMI online CAD Configurator to design shafts to their specifications and then download the corresponding native CAD files directly from the MISUMI website. This revelation made ABCO quickly realize that it would be far more cost and time effective to procure MISUMI linear shafts instead of blank linear shafts, requiring secondary machining operations, which had been ABCO’s previous workflow.

From this realization, ABCO began investigating other custom components they could replace with MISUMI configurable components. “We found that by reducing the number of custom components per machine we are able to not only save time and money but are also able to produce machines that are more modular and offer better performance,” explained Senior Mechanical Engineer, Dan Pescariu.

ABCO Chooses MISUMI’s Configurable Component Solution

As ABCO increased its use of configurable components within designs, the benefits associated with decreasing the use of custom components was soon realized on a larger scale across a number of diverse projects. “When we first started doing business with MISUMI, I was immediately impressed with the precision that goes into every component and the fact that what you configure is what you get,” said Pescariu.

ABCO had experienced problems with custom components mostly due to the fact that no two components were exactly the same. As Pescariu explains, it’s common to occasionally come across a “one of a kind” component that can’t be copied exactly.

However, it’s easy to design a configurable component to the required specifications and then simply reorder that particular component whenever it is needed by procuring the part using the component’s part number. To this end, the machine component modularity increases as the configurable components are introduced in an increasing number of machine designs. In total each packaging machine contained approximately 10,000 components. Out of the approximate 10,000 components, around 3,000 were MISUMI components.

At ABCO, this turned out to be the deciding factor when choosing MISUMI as a supplier for the design and build of several high-speed, high-performance packaging machines. “As is typical in this business we were under an extremely tight deadline and also knew that we would have to duplicate this machine and build the exact machine several times for this customer,” explained Pescariu. ABCO Sales Engineer Paul Mellander further explained that in the custom machine design industry, duplicating machines can be a significant challenge to overcome, especially when dealing with custom components.

This is why Pescariu began studying the MISUMI catalog to better understand how many configurable components ABCO could use on these machines. “Unlike custom components, MISUMI configurable components offer native CAD files that can be downloaded from their website as well as short lead times, published prices and part numbers for every configured component, which can easily be added to the bill of material,” noted Pescariu. Mellander adds that these features take the guesswork out of the design process, and the available native CAD files save large quantities of engineering time.

This, coupled with the fact that MISUMI does not have a minimum order quantity or set-up charges and boasts a 99.95% on-time delivery rating for all its products, shows that MISUMI brings a significant amount of value to its customers. “The deadline for the design and build of these packaging machines was just a couple months, but once I knew that we were using MISUMI as a supplier I felt more comfortable committing to such a tight deadline with the customer,” explained Mellander.

Reducing the total of components needed for machinery

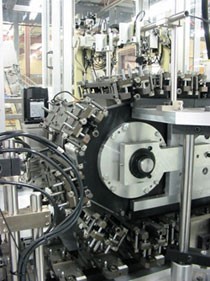

With the speed and performance that was needed for these packaging machines, the design and build process must be flawlessly executed. As Pescariu explained, when dealing with multi-axis machines with high speed and high-performance requirements, the company cannot afford design compromises because the design inherently requires high precision components. As mentioned earlier, Pescariu was extremely impressed with the quality and precision of MISUMI configurable components, which made him comfortable using MISUMI to source components for this particular project. The MISUMI component list for this machine included linear shafts, flanged linear bushings, strut clamps, locating pins, locating bushings, belts, bearings, plates, bolts and rollers.

By using configurable components instead of custom components, Pescariu found that he was able to significantly reduce the total component count of the machine. According to Pescariu, this accelerated the machine design and build process because the machine components fit together so well. This also led to a shortening of the machine testing phase as well; taken together, both of these factors contributed to the massive success of the machine design and build. Additionally, the machine was easier to duplicate which should lead to long-term benefits including lower maintenance and less machine downtime.

Reducing component count equals cost savings

ABCO President Brad Kemmerer expects his engineers to meet their design and build budgets and encourages them to beat the budget consistently. “We were able to come in under budget for the design and build of these packaging machines and I can honestly say this is due to using as many MISUMI components as we could on the machine,” stated Pescariu. In total, each packaging machine contained approximately 10,000 components. Of these, approximately 3,000 were MISUMI components.

“Making one-third of the machine from MISUMI played a huge role in the success of this project,” stated Pescariu. He then further explained previously ABCO would have had to draw and machine many of these components. “For a project of this size if we would have needed to draw and machine all the mechanical components, it could have increased the tooling costs by 5 times,” estimated Pescariu.

Sales Engineer Paul Mellander further explained that before the company discovered MISUMI, on a project of this size, it was easy for ABCO to max-out the capacity of all the local machine shops as they attempted to fabricate all the custom components required for the project. However, by replacing the custom components with configurable components this is no longer a problem. “Coming in under budget for a project of this size is huge for us and our customer and makes us understand the importance of the configurable component,” noted Mellander.

The long-term benefits of MISUMI’s configurable solution

Working with configurable components has really changed the thinking behind designing and building custom machines at ABCO Automation. Pescariu explained that previously the idea was to first design the machine then spec as many standard components as possible, backfilling the rest with custom designed components. However, now the thinking is: first specify the standard components, then specify as many configurable components as possible.

In turn, this decreases the number of custom components and ABCO directly reaps the benefits. ABCO believes that using MISUMI as a supplier of configurable and standard components has greatly benefited the business as it directly benefits ABCO customers as well. “I’ve never seen a company that announces yearly price reductions on its most popular products, but as MISUMI reaches higher sales volumes on these products the production costs decrease and MISUMI passes these savings on to ABCO,” stated Pescariu.

Along with competitive pricing, MISUMI never requires a minimum order quantity or set up charge on a product portfolio of 280,000 metric and inch components. Additionally, MISUMI has a 99.97% on-time delivery rating on all its products and a web portal that allows engineers to download native CAD files and place orders on its entire product catalog.