MC Machinery Systems is offering on-site demos of the new ASTES4 High Speed ADVANCED, a modular sorting system that can cut sort times in half, reduce labor costs, improve throughput and eliminate bottlenecks.

The new system is a solution for fabricators facing worker shortages and bottlenecks resulting from the increased productivity of higher-volume fiber lasers. The high-speed modular sorting solution significantly maximizes the productivity and efficiency of downstream operations.

The ASTES4 High Speed ADVANCED can be integrated with the SmartFlex RAPID automated sheet loader and a Mitsubishi fiber or CO2 laser.

The ASTES4 High Speed ADVANCED features:

The ASTES4 High Speed ADVANCED features:

- A patented, integrated tool-changer head with six programmable tools

- Four sorting heads with a capacity of up to 220 pounds per head

- Mitsubishi Drive components that allow seamless communication between the control, servos and drive system

- Multiple customizable configurations

- Tighter proximity between picking heads

Benefits of the new laser automation system include:

Benefits of the new laser automation system include:

- Can reduce sorting time by half

- Elimination of manual tool changing

- Increased worker safety

- The ability to run unattended

- Lower labor costs

- Reduced setup time

- High-speed precision, with a high success rate of picks even at high speeds

- Reliability

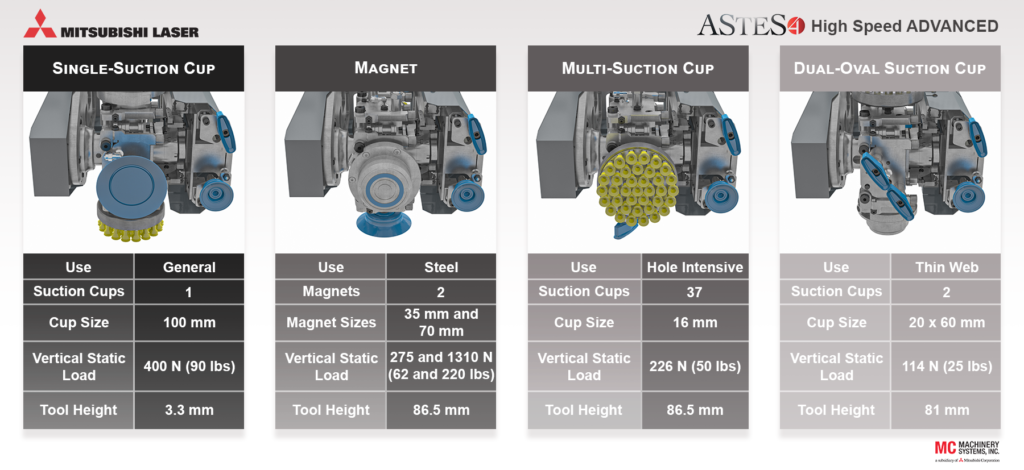

The ASTES4 High Speed ADVANCED features multiple tools on each head, including:

- Single suction cup tool

- Magnet tool (featuring two sizes)

- Multi-suction cup tool

- Dual-oval suction cup tool

- Out-of-center tool for small or heavy parts that require two lifting points

“The ASTES4 High Speed ADVANCED can solve problems faced by just about every fabricator, including worker shortages, high labor costs, production bottlenecks and more,” said MC Machinery North American Sales Manager for Fabrication Shane Herendeen. “The patented tool-changer head with programmable tools makes it the most adaptable and customizable sort system available.”

ASTES4 SA is a Swiss-based company acquired by Mitsubishi Electric in 2018. MC Machinery Systems, headquartered in Elk Grove Village, Ill., is a subsidiary of the Mitsubishi Corp. and a Mitsubishi Electric automated solutions partner.

To arrange an in-person demo of the ASTES4 High Speed ADVANCED at MC Machinery’s Chicago-area headquarters, visit https://www.mcmachinery.com/astes-hs-advanced.

About MC Machinery

A subsidiary of the Mitsubishi Corp. and headquartered in Elk Grove Village, Ill., MC Machinery Systems is a premier North American supplier and servicer of fabrication and milling equipment, including Mitsubishi lasers, press brakes, EDMs and automation systems. Serving industries including aerospace, mold and die, job shops, medical and energy, MC Machinery offers a large, regionalized service network, an experienced application support team and multiple technology and training centers in the U.S., Canada and Mexico.