Tormach Inc., the industry’s leading supplier of affordable and compact CNC machines, has announced its newest machine, the 8L Lathe.

This new 8L Lathe is a small machine with big capabilities, and has the ability to fill turning needs in a variety of spaces. Rigid enough to cut anything, whether it’s plastic, stainless steel even titanium, this machine can handle it, and at an approachable price point. Starting at $6,595 for the basic machine with tailstock and fully-assembled enclosure, an 8L Lathe Deluxe Package with numerous features including a robust machine stand with integral coolant tank, separate chip drawer for easy removal, storage drawers and optional side shelving, as well as PathPilot controller, tool holder/tool kit, monitor, keyboard, mouse, and more is available for only $8,875. And the fully-loaded 8L build comes in under $10K.

“We are excited to introduce this new lathe to the market,” said Cory Bailey, Tormach’s Product Engineer. “Tormach was founded on the idea of bringing cost-effective and capable CNC equipment to market and this one provides users with everything needed to face, turn, bore, groove and thread. We know of no other machine that offers such advanced software and capabilities at such an affordable price.”

The 8L lathe features a 5C spindle that accommodates parts up to 1” diameter, which meets the needs of most lathe users. For larger pieces up to 8” in diameter, users can simply add a 3- or 4-jaw chuck to cut the stock.

Like all Tormach CNC machines, the 8L lathe will be controlled by the PathPilot software system. That means users can use intuitive conversational lathe programming, do rigid tapping, and leverage built-in Dropbox™ support for transferring programs. PathPilot and PathPilot HUB has been known to be incredibly powerful for both beginner CNCers, as well as veteran machinists and educators.

Specifications

Specifications

The new 8L is unique, not just among other Tormach machines, but also in the general machine tool market, because it offers a 1.5 HP (1.11 kW) spindle that runs at 180-5000 RPM. It already comes with the machine in a fully assembled enclosure as part of the base model, but the footprint remains small (26in. x 50 in.), and the lathe itself is attached to a hand-scraped 140-pound cast base. Like all Tormach machine tools, the 8L runs on standard single-phase household power (115 Vac, 50/60 Hz, and a 15 A breaker).

With a 5C spindle, the 8L can accommodate parts up to 1 in. or use a 3- or 4-jaw chuck, providing a swing of up to 8”. And, the stepper motors on the X and Z axes provide a feed rate of 150 IPM (3.8 m/min).

Travels on the 8L are impressive for its compact size. The maximum workpiece length is 10” with the tailstock. The X-axis travel is 4.5”, so users can accommodate a part that fully utilizes the 8” swing.

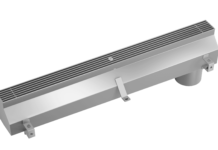

It’s configured for Industry Standard OXA Quick Change Tool Post. Instead of the operator needing two wrenches that turn hardware in opposite directions, the machine itself can lock down the tool holder. By allowing ‘one hand tool changing’, this takes a typically inconvenient task and not only makes it easier, but also greatly reduces the time required to change the tooling.

About Tormach

Located in Waunakee, Wisconsin USA, Tormach Inc. is dedicated to providing exceptionally engineered products, technical support, and customer service at the lowest possible cost. Our focus is to help our customers realize goals in CNC by providing tools and resources to help transform concepts into real products.

Whether you are involved in research and development, education, short run production, or simply an entrepreneur with an idea, Tormach small CNC products will allow you to make what you need easier, quicker, and more affordably.