In the forging industry, the recent economic slump, disruption of the international supply chain and consolidation among forge operations has created a potential opportunity for domestic operators to pick up new business in 2021.

However, forgers must be poised to satisfy demand, as well as take advantage of additional business that gets reshored as North American manufacturers look to shorten lead times and the supply chain with domestic suppliers.

So, forgers looking to rebound in the new year would be wise to consider the proverb, “Luck is what happens when preparation meets opportunity.” With this in mind, many forgers are now wisely taking this time to prepare for opportunity. This means re-evaluating their processes and seeking out new ways to improve production efficiency as part of their post-crisis rebound and recovery strategy.

So, forgers looking to rebound in the new year would be wise to consider the proverb, “Luck is what happens when preparation meets opportunity.” With this in mind, many forgers are now wisely taking this time to prepare for opportunity. This means re-evaluating their processes and seeking out new ways to improve production efficiency as part of their post-crisis rebound and recovery strategy.

To the extent funding is available, that includes finding fast, economical ways to repair or acquire equipment that will enable production at higher volumes. For the far-sighted, it can also mean rebuilding or even remanufacturing equipment to take advantage of high-production, labor-saving automation.

Rapid Repair

Scheduling necessary repairs is the obvious first step to be ready for an economic rebound in the new year.

“The most immediate and economical option is to repair existing or out-of-commission units to get them up and running to spec with greater efficiency. This can be as simple as replacing parts that are worn, out-of-tolerance, or broken to bring the machinery back online,” says Ken Copeland, president of Ajax-CECO, a manufacturer of forging equipment since 1875.

In recent years, the company has continued to expand into a one-stop, expedited domestic source for forging equipment with the acquisition of Erie Press Systems under parent company Park Ohio (NASDAQ: PKOH). As a result, the company is now the largest OEM forging equipment supplier in North America.

According to Copeland, the most needed repairs on forging equipment usually involve perishable items that are common to every machine, including friction plates and driving plates for presses and upsetters, or piston heads, rods, rings and packings for hammers.

He says that the parts for these most needed repairs should be in stock at reputable domestic suppliers.

“However, forging operations can still get into trouble when a part they need to replace was built decades ago and the forger doesn’t know if the OEM is in business or if a drawing of the part exists,” he points out.

According to Copeland, when forgers end up sending parts to machine shops to be reverse-engineered and machined, problems occur. Machine shops often do not have access to critical specifications about high wear parts including the material grade of the steel, the heat-treating process utilized and tolerances that all were engineered specifically for that piece of equipment.

“The result can be parts that prematurely wear or fail,” he cautions.

Instead, it is often a better choice to rely on OEMs like Ajax-CECO, which offer stocking programs for long lead time items such as main gears, eccentric shafts, rams, etc. that are usually not stocked by forgers due to the cost. In this type of program, the part is held in inventory for the forger. The forger pays a percentage of the cost and then the balance when they take possession of the part – even if years later.

Instead, it is often a better choice to rely on OEMs like Ajax-CECO, which offer stocking programs for long lead time items such as main gears, eccentric shafts, rams, etc. that are usually not stocked by forgers due to the cost. In this type of program, the part is held in inventory for the forger. The forger pays a percentage of the cost and then the balance when they take possession of the part – even if years later.

According to Copeland, a custom stocking program with minimal up-front investment can eliminate months of downtime due to long lead time parts. Instead, multiple machines with parts of similar size and design can have the parts manufactured to a semi-finished state in preparation for use with any of the machines. When needed, the exact dimensions for the down machine can be provided so the part can be completed to spec, ready to install.

With the economy still down, however, most forgers are less comfortable with placing a purchase order for a new machine that may take one year to deliver. Instead, they want more economical options that can be brought online quickly.

In this way, a rebuild or remanufacture of existing forging equipment are still feasible options. A plus to this approach is that high-productivity, labor-saving automation can be added.

Expedited Rebuild and Remanufacture

When the scope of work goes beyond repair, a machine rebuild is an economical, accelerated option to bring additional equipment online.

“Depending on the scope of the work, equipment rebuilds are ideal because the process can take as little as a few months to be operational. In a rebuild, all high wear items such as bearings, bushings, seals and liners should be replaced to get the machine in good working condition,” says Copeland.

According to Copeland, rebuilds can be performed on-site or the unit can be shipped to the OEM’s manufacturing facility, which reduces the rebuild costs. Once there, the machine is completely disassembled, cleaned and inspected. Upon completion of the inspection, a report of findings is submitted to the customer that includes a list of missing components as compared to the “as-built” Bill of Material; findings of concern that might impact operation; and a description and pictures of the general condition of the parts. This comes along with a general scope of work and price estimated for the rebuild and re-commissioning of the machine.

If even more extensive work is required, remanufacturing the equipment can still save time over buying new.

“Remanufacturing basically means stripping down the machine to the cast frame and replacing all the internal parts,” says Copeland. “With a remanufacture, you save time having a new frame cast. Remanufacture can be completed faster than buying new at about 85% to 90% the cost, and would usually carry a new machine warranty.”

“Remanufacturing basically means stripping down the machine to the cast frame and replacing all the internal parts,” says Copeland. “With a remanufacture, you save time having a new frame cast. Remanufacture can be completed faster than buying new at about 85% to 90% the cost, and would usually carry a new machine warranty.”

One of the advantages of rebuilding or remanufacturing forging equipment is that the scope of work can also include adding significant automation upgrades.

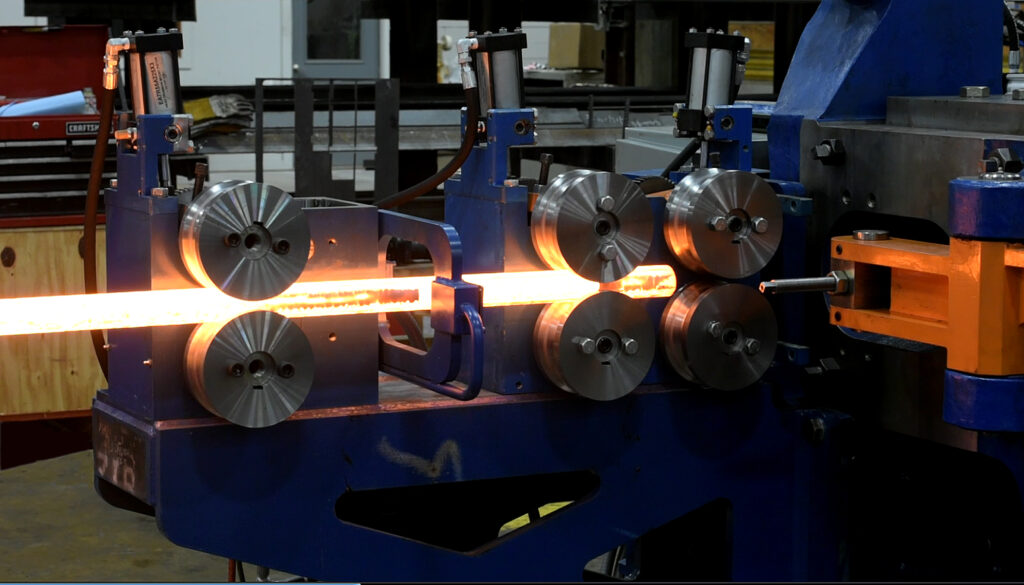

Many of the tasks that are performed manually – such as moving heavy steel rods, pipe and other stock in and out of equipment – can be automated. This could be with the mechanical “hand” of a robot or by integrating servos that can lift, insert and deposit materials. Even tasks such as automated tooling changes can be completed with the push of a button.

Automation creates a safer environment for forging operators and increases productivity. “By automating forging operations to perform some of the tasks of a human operator, productivity can increase from several hundred pieces per hour up to 3,000, depending on the type of products being forged. At the same time, it gives the plant the ability to maintain recommended social distancing,” says Copeland.

Preparing for Opportunity

While forgers are preparing for an expected economic rebound in 2021, now is actually a good time to work with forging equipment OEMs.

One of the challenges forging shops still face in 2020 is shutting down the line for repairs for any length of time. However, equipment OEMs can work with forgers to develop a plan to minimize downtime by reviewing the machine’s bill of materials, reviewing past repair orders and manufacturing key components that will need to be replaced.

In addition, the OEM has the original design specifications, critical materials and clearance specifications to jump on repairs or rebuilds and quickly get the work done. Information such as critical data on high-wear parts, the material grade of the steel, the heat-treating process that was used, and the required clearances that were used in the engineering of that particular forger are all needed for a quality repair, rebuild, or remanufactured.