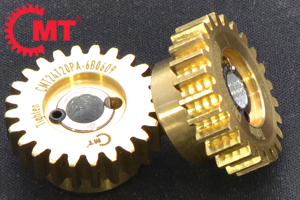

Custom Machine and Tool Co., Inc.’s brass spur gear bored to accept the patented Concentric Maxi Torque, a keyless connection bushing system. Spur gears are common gears that transmit motion between two parallel shafts. Used in applications that require speed reduction and torque multiplication such as size reduction equipment, consumer appliances, trains and bicycles.

Brass Spur Gears Features & Benefits:

- Brass gears teeth are hardened due to constant meshing. Gears exposed to harsh environmental weather or chemicals are protected due to the hardening.

- Spur gears are suitable for driving systems due to having more power transmission efficiency.

Gears with the Concentric Maxi Torque:

- Flexible positioning enables customers to easily phase, install, adjust and remove drive components, all while offering precise component positioning.

- Concentric Maxi Torque provides uniform surface contact eliminating shaft damage.

- Concentric Maxi Torque offers a compact design.

- Improves hub-to-shaft concentricity.

- Speed and ease of assembly.

- Reduces inertia.

Engineers at Custom Machine & Tool Co., Inc. found that fasteners used to connect components to high-speed shafts had to have low inertia and few vibrations. They also knew that component alignment, accuracy, holding ability, and runout became more critical at higher speeds. There was not a compact bushing for shafts less than an inch in diameter that could handle all these tasks. So they decided to design and build one. The result, the Concentric Maxi Torque bushing.

How It Works: A single setscrew locks the low-taper angle-split bushing in place without cocking, using a locking-taper design. The same screw is also used to unlock the connection and users reposition the bushing and component. The bushing applies uniform force along its full contact with the shaft. And the bushing can be detached, moved and reattached multiple times without damaging the shaft or losing holding torque. The bushing has low inertia, so there’s better shaft-to-component balance. They come in sizes to cover bores from 0.1250 to 1.1875 in. (3 to 30 mm) with torque capacities from 35 to 3, 500 in. lb. (4 to 410 Nm). Radial runout is less than 0.001 in. (0.026 mm).

Custom Machine & Tool Co., Inc. has been a US manufacturer of timing pulleys, drive systems and components for the motion control and power transmission markets since 1964.