In this age of digital information, it is prudent to utilize the data generated by production machines to monitor processes in real-time and then analyze the collected data to determine opportunities for improvement. To stay profitable and consistent, real-time measurements and continuous improvements are necessary. This goes for large-scale and small-scale operations alike.

Real-time data also enables automated machines and software systems to automatically make decisions based on satisfying a set of conditions. All of this can only be achieved through the interconnectivity of machines and their ability to communicate data in real-time, or what is considered the basis of today’s Industry 4.0.

Value of Process Improvement

If you are a fabricator, you understand the value of measuring a production process and the continuous improvement of that process. Each company inevitably develops its own unique processes and must continue to improve them over time. This is just as true for smaller size operations as it is for large operations.

But why is process improvement so important? Because a company’s unique “process” is one of the key competitive differentiators that each company has and must continuously improve to remain profitable and viable. An efficient process helps to keep a shop and its products profitable.

Process improvements, however, cannot exist without measurements. Continuous improvement requires accurate information and data, both to validate and to further enhance the process.

Companies can incorporate two types of measures, batch and real-time. Batch is when you start the measure at the beginning of the process and then finish it when that process is completed.

The problem with batch measures is that they do not provide the ability to take measurements of a process in real-time. You must wait until the entire process is completed to determine its final actual production time.

If there was a degradation of performance during the process and it was not identified and corrected, it would result in a higher-than-expected cost due to a longer processing time.

Real-time measures, on the other hand, are based on real-time data communicated by production machines and centrally collected for analysis. Standard measures can be compared against actual measures to determine if the process is on track. Problems can be identified, and corrections can be made immediately in real-time before that process is completed.

Staying competitive

Every fabrication shop must be competitive. That’s a given. Its unique workflows and processes must be efficient in order to stay competitive. And there are two ways to accomplish this.

The first method is to exhaust the capabilities of your current machines and workflow efficiency. The only way to know if you have achieved this is to measure each process and measure the non-productive times, as well. Are the opportunities in the process itself or is it in the non-productive setup and waiting times?

Measurements not only improve processes, they can also help determine when new equipment is justified.

Justifying the cost of new equipment to management is always based on performance metrics and costs. How much availability has there been on the machine? How much lost production time is attributable to unscheduled machine downtime? Has the machine reached its “end of life cycle” where maintenance costs are now eating too much into profit margins and contributing to lost productivity, not to mention longer delivery times? Also, what is the cost of the new equipment or software and how long is the return on investment?

The second method to maintaining a competitive edge is to invest in new equipment and software systems. For smaller shops, big investments like these can sometimes come with hesitation. But they can be justified if you have the data to prove that you need the new equipment and how the new investment will generate a quick return on investment, higher productivity and efficiency, and greater profit margins.

Yet another benefit to maintaining metrics is that you will already have the data for your current processes and will be able to compare that to how the new equipment or software system compares.

One additional thing to consider is the possible increased machine availability derived from new technology.

For example, when looking at fiber laser technology and considering the productivity benefits of cutting two to three times more parts per unit of time, and consuming less than half of the operating costs compared to CO2, it is fairly obvious why fiber lasers have become so popular.

But these are considered tangible potential profits based on performance metrics, such as speed and cost of operations. The intangible potential profits are derived from the additional machine capacity that is being created. Because you are able to produce two to three times more parts, you have now created more machine capacity to cut even more parts. Because you are more cost competitive, there is also the added flexibility to expand into industries you were unable to compete prior to purchasing the fiber laser.

Interconnectivity of Machines

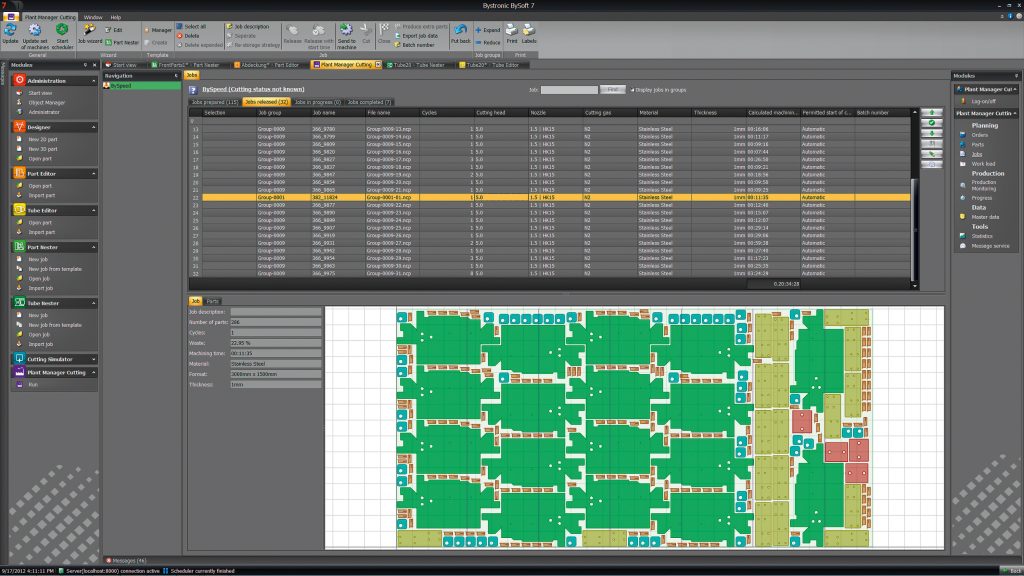

Real-time data communications allow automated systems to make decisions based on satisfying a set of conditions. When an ERP system releases an order to a production management system, the system can organize and schedule the order based on due dates and combine them with other orders of the same materials to maximize material utilization.

From there, automatic nesting software creates the nests based on the accumulated orders and can automatically release the nests to the cutting machines based on achieving a minimum material utilization value. Once the machines receive the nests, automated material storage and handling systems are directed to retrieve the correct materials for each nest.

Subsequently, as the machine completes the cutting process, the material handling system automatically unloads the cut parts and can even sort them. All of this can be achieved with automated systems and the benefits of its interconnectivity.

Modern machine tools are capable of generating real-time data regarding production times of nests and even individual parts. They are also able to generate machine related data for analyzing machine performance metrics, such as machine availability and machine uptimes.

Real-time data and the interconnectivity of machines with web enabled devices, such as web cameras, tablets and smartphones, enables managers to monitor systems in real-time regardless of their locations. The interconnectivity of machines enables automated systems to make decisions based on the prior process having achieved its objective. In these “real-time” capabilities are just some of the benefits of Industry 4.0, based on the interconnectivity of machines and their ability to communicate data in real-time.