Several of MC Machinery’s product and application experts will be on hand to meet with attendees and host live demonstrations of some of the machine builder’s most popular and innovative milling, wire and sinker EDM equipment. MC Machinery will be located at booth #2430 in Hall 2. The featured machinery on display will include:

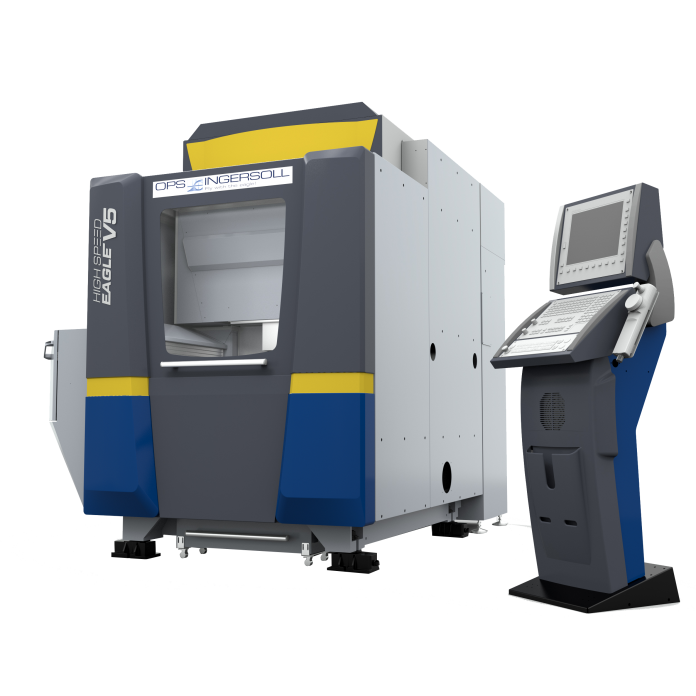

OPS Ingersoll Eagle V5 5-Axis Milling Machine

Capable of simultaneous 5-axis machining, the Eagle V5 is built for rigidity and fine precision. Its 15.75-inch table has a capacity of 550 pounds. The machine is also built with a 42,000-RPM, integrated spindle, a heavy-duty, roller-type linear glass scales in both the X and Y-axis. It also comes standard with a HEIDENHAIN iTNC-530 control unit mounted on a moveable pedestal for convenient positioning.

DV800 CNC Milling Machine

Built for general-purpose or intricate milling work, the DV800 includes a 15,000-RPM direct drive, BIG Plus spindle. The versatile machine includes the MITSUBISHI M80A Series control with a 15-inch touchscreen with cell phone-like functionality and 135,000 block per minute calculation speed.

EA12S Advance Sinker EDM

The EA12S Advance features the most advanced, easiest-to-use MITSUBISHI control yet, the M700 with a 15-inch touchscreen. The machine’s unique FP89S energy saving power supply reduces electrical consumption 20 percent more than the previous FP generation. GF2 Adaptive Control reduces electrode wear as much as 80 percent while the new SS Jump 5 optimizes acceleration to stabilize high-sped, no-flush burning.

MV1200-S Advance M800 Wire EDM

Ideal for small-part manufacturing, this sinker system includes powerful standard features like auto-threading, internal machine communication and power supply control technology. Another step in Mitsubishi EDM’s continued focus on improvement, the machine includes the revolutionary M800 series control with a 19-inch cell phone-like touchscreen control with common shape macros that can reduce programming by as much as 88 percent.

About MC Machinery

MC Machinery Systems customers get the best of both worlds: A single source for a diverse arsenal of manufacturing technologies and our expansive and knowledgeable support network. Our expertise spans virtually every aspect of metalworking—from simple fabrication to CNC-driven, automated manufacturing cells.