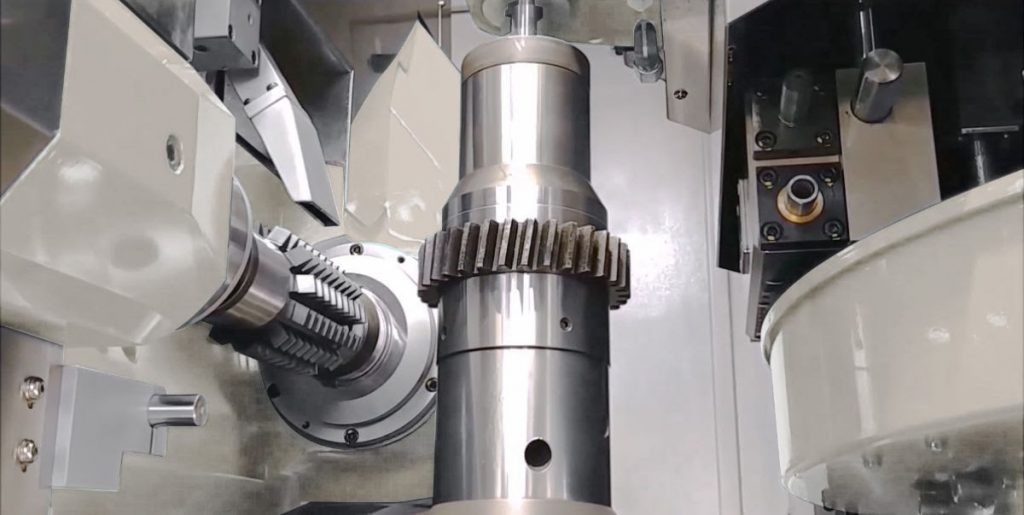

Helios Gear Products (formerly Koepfer America) exclusively offers the Helios Hera 350 gear cutting solution from YG Tech. This CNC gear hobbing machine offers advanced technological features such as FANUC 0i-MF control and servo motors, X-axis linear scale for accurate repeatable control of size, work spindle with direct drive torque motor, automatic retract of X-axis at power failure, and more. With a globally competitive price, proven domestic support from Helios, and a unique combination of technical capabilities, the Hera 350 offers gear manufacturers a world-class hobbing solution.

The Hera 350 offers 6 CNC axes (7 with automation), a 6 module (4.23 DP) pitch rating, and 1,200 rpm maximum hob speed. Additionally, this machine has a radial travel of 280 mm (11.000 in) from 35 mm (1.380 in) to 315 mm (12.400 in) center distance between the work and hob axes, which allows a wide range of part sizes for universal gear cutting. For long cutting tools, the Hera 350 offers hob shifting up to 180 mm (7.087 in). The machine has a maximum tailstock position of 760 mm (29.921 in) and a maximum axial travel of 470 mm (18.500 in), which rounds out the machine’s versatility for manufacturers. With the Hera 350, both job shops and end-product gear manufacturers will find flexibility and capability. David Harroun, sales manager for Helios Gear Products says, “The Hera 350 is a cost-effective and highly capable machine that gear manufacturers are going to want on their shop floor.”

With the Hera 350, both job shops and end-product gear manufacturers will find flexibility and capability. David Harroun, sales manager for Helios Gear Products says, “The Hera 350 is a cost-effective and highly capable machine that gear manufacturers are going to want on their shop floor.”

The Hera 350 also offers impressive streamlined dialog programming in the base package with visual examples to guide users and accelerate training. Operators can easily enter data on a large color touchscreen panel for cutting one or two gears on a single workpiece using single- or two-cut cycles with radial, axial, climb, or conventional hobbing (or any combination thereof). Additionally, crowning (lead modification) and automatic shifting over a damaged hob section are included. Manufacturers will appreciate the machine’s ease-of-use and how quickly operators can be trained.

The machine’s compact enclosure is enveloped at 3.710 m (12.2 ft) wide by 2.150 m (7.1 ft) deep by 2.790 m (9.2 ft) high. Moreover, the machine offers safety features such as electro-mechanical interlock and a splashguard door. The machine’s cast iron base provides superior dampening and stability for extreme cutting conditions.

The YG Tech Co., Ltd., owner of the “Hera” brand, has constructed gear cutting machine tools since 1963, and the Hera series started in 2004, having grown to hundreds of installations around the world. Helios Gear Products is excited to offer and support the Hera line in North America with 30+ years of experience in machines, tools, engineering, and technical support.

About Helios Gear Products, LLC

Helios Gear Products, LLC specializes in the parallel axis gear industry and offers hobbing machines with optional automatic loading systems, worm and thread milling machines, gear inspection equipment, deburring and chamfering machines, consumable tools (including hobs, gear grinding and honing wheels), hob and shaper cutter sharpening machines, and expert services for hob sharpening and part inspection. Helios products are used worldwide, and our experience gives us the edge in contributing to the productivity and efficiency of our customers. Helios Gear Products, LLC services the North American market for YG Tech Co., Monnier + Zahner / Lambert−Wahli, Tecnomacchine, and Tyrolit−MIRA. Helios also offers cooperative sales and service with Kapp Technologies and Penta Gear Metrology.

Helios Gear Products, LLC

635 Schneider Drive

South Elgin, IL 60177

Adam Gimpert | Business Manager

P: 847-931-4121