If you’re engaged in welding, cutting, grinding or other dust-producing processes, air filtration is essential. But are you spending more than you should to replace filter media?

Most companies are well aware of the need for regular preventative maintenance (PM) on their dust collectors, including filter changes. Filter replacement is one of the biggest variables in ongoing operational costs for your dust collection equipment. Change them too often, and you are throwing money away. If you don’t change them often enough, your air quality will deteriorate. Your equipment will also have to work harder, driving up energy costs.

Fortunately, there are ways to extend filter life for your air filtration systems and reduce ongoing operational costs. Here are five filter-saving strategies to consider when evaluating equipment, choosing filter media and developing maintenance schedules.

1. Choose the Right Filter for the Job

First and foremost, make sure you are using the right filter media for your applications. Are you using thermal applications (such as welding) that produce invisible fumes, or are you engaged in cutting or grinding applications that produce larger particulates? Do your processes produce oil mists? How toxic are the particulates? And what is the volume of fumes or dust produced?

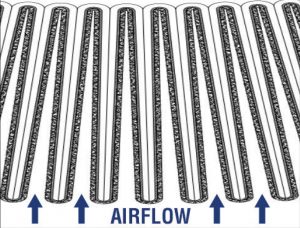

It’s important to select the right filter media for the size, types and volume of particulates that are produced by your processes. Filter design, matters, too: not all filters are created equal. Cheap off-brand replacement filters may end up costing you more in the long run if they need to be replaced more often. Pleats should be designed to allow proper airflow throughout the media to maximize their loading potential. Without correctly designed pleating, airflow does not make it to the interior portion of the filter, essentially cutting its loading potential in half.

It’s important to select the right filter media for the size, types and volume of particulates that are produced by your processes. Filter design, matters, too: not all filters are created equal. Cheap off-brand replacement filters may end up costing you more in the long run if they need to be replaced more often. Pleats should be designed to allow proper airflow throughout the media to maximize their loading potential. Without correctly designed pleating, airflow does not make it to the interior portion of the filter, essentially cutting its loading potential in half.

2. Size Your Filters to Your Airflow Requirements

To optimize filter life, you need to make sure you have enough filter area for the volume of air that you need to move. Airflow, measured in cubic feet of air per minute (CFM), will be dependent on the size of the space the dust collector must support and the volume of particulates you are producing. The higher the CFM, the more filter surface area you will need. This is known as the filter velocity or, to use an old term, air-to-cloth ratio.

Sizing your filter properly for your CFM is one of the most important considerations in system design. If the filter velocity (air-to-cloth ratio) is too high, particulates are driven deep into the filter media before they can be pulsed off, causing rapid filter clogging (also known as blinding) and reducing filter life. One way to reduce the filter velocity is to reduce the CFM needed for effective filtration. This can be accomplished by minimizing the volume of air that must be collected by using source capture systems or putting properly-sized hoods over fume-producing processes. The less air you need to move, the less filter media you will need.

3. Blow Everything Off

Pulsing systems can significantly extend filter life by blowing the particulates off the surface and into the collection bin before they become entrapped in the filter media. This is known as Reverse Jet Pulsing. The longer you can keep the filter media clear, the longer you can go between filter changes. Manual pulse systems rely on maintenance staff to remember to turn them on at the end of each shift when the dust collector is turned off.

Automated pulsing systems will do this periodically while the dust collector is in use. RoboVent’s patent-pending Dynamic Pulse system goes a step further: it uses a synchronized pulsing mechanism to prevent re-entrainment of dust onto neighboring filters. These systems can increase filter life by 30%-50%.

4. Think Vertically

Filter life is also impacted by filter orientation. Dust collectors with vertical filter orientation increase the efficiency of pulsing systems and improve filter life by letting gravity do some of the work. With filters in a horizontal configuration, dust from higher filters falls onto the filters below, reducing the effective surface area and consequently increasing the filter velocity on the rest of the filter. With vertical orientation, dust falls down between the filters instead of falling onto filters beneath. The simple decision to use a vertical filter unit will increase filter life by 20-30%.

5. Optimize Your Maintenance Schedules

5. Optimize Your Maintenance Schedules

Finally, make sure you optimize maintenance schedules for your equipment needs. Many companies perform PM on a regular schedule, regardless of actual equipment usage. A regular schedule is easy to manage and will go a long way towards extending equipment life and improving efficiency.

However, if your processes are variable, it may mean that sometimes filters are thrown out while they still have usable life left simply because they are on the schedule. In other cases, they may be left in too long for optimal efficiency. For this reason, some companies are moving to predictive maintenance schedules that are more closely tied to actual equipment use.

Predictive maintenance controls rely on computer algorithms that monitor equipment use and calculate filter replacement intervals to optimize cost and performance. For example, the RoboVent eTell smart control system uses machine learning to learn schedules and processes over time and predict remaining filter life and maintenance needs for each dust collector. It’s like the “miles-to-empty” notification on your car. These systems can significantly improve dust collector efficiency and help companies reduce maintenance costs by targeting efforts where they are truly needed.

Your filters perform an essential role in protecting employees from dangerous particulates that can impact their health and comfort. Proper air quality system design, maintenance and filter media selection will ensure that they can do their job efficiently and effectively. Extending filter life can significantly reduce the cost of clearing the air in your facility.

About the Author

Greg Carmichael is the North American VP of Sales for RoboVent, the leader in clean air solutions for the manufacturing industry. In addition to his management experience, he has more than ten years of boots-on-the-ground experience in dust collection design. Greg has a knack for sensing the need of the client and designing practical, functional and effective solutions that meet multiple criteria such as facility safety, effective handling, lower maintenance and best practice designs.