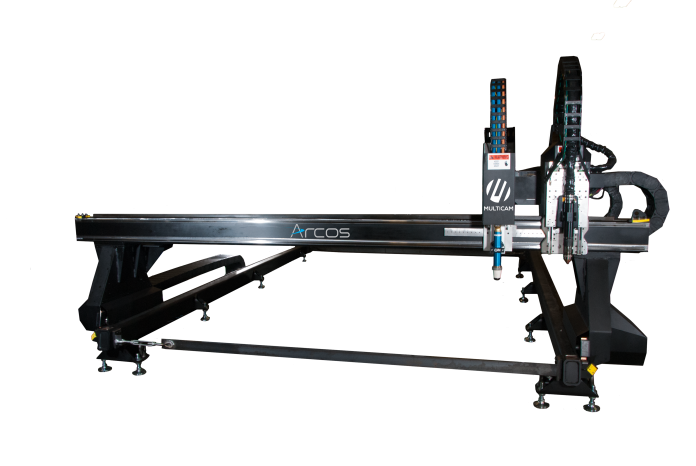

Engineered and manufactured at their North Texas headquarters, MultiCam’s Arcos Bridge & Rail System combines exceptional motion and high fire-power to provide end-users the flexibility to accurately and effectively process heavy plate material. With modular machine sizes ranging from 6’ x 12’ up to 10’ x 27’, the Arcos Bridge & Rail System is design around commonly available raw material sizes.

The Arcos Bridge & Rail combines an industry-leading Hypertherm XPR300 Plasma System as well as a state-of-the-art IHT Automation OxyFuel Torch which features AutoGas, AutoLight, AutoHeight, and AutoPierce functions. The Arcos also features an integrated material database so end-users can simply use a menu-drive system to adjust feed rate, pierce-delay, pierce-height, and many other options automatically. By fully automating the cutting process of each torch, end-users are able to optimize their production quality and efficiency all while reducing common operator errors.

About MultiCam

MultiCam is a global supplier of innovative CNC cutting solutions for industries ranging from sign making to digital finishing, sheet-metal to plate-steel processing, hardwoods to cabinet making, thermoform trimming to plastics fabrication, as well as a wide variety of aerospace and automotive applications. With over 13,000 machines installed worldwide, MultiCam provides cost effective, easy-to-use, programmable cutting, and additive manufacturing solutions for both large and small companies alike.

Founded in 1989, MultiCam’s corporate office and manufacturing facility is located in the heart of Dallas-Fort Worth, Texas. With over 50 technology centers across the globe, along with sales and service representatives in over 100 countries, you’ll find a location near you for local demonstrations, training, service, and support.