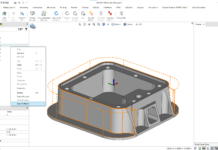

Automated cutting and bending systems digitally networked with an overarching software architecture that guides sheet metal parts on the optimal path through the individual process steps: from the incoming order data, to the programming of the cutting and bending plans and the best possible allocation to the available capacities of the integrated machine systems, all the way through to the delivery of the finished sheet metal products. In the whole process, sensors measure each step and thus enable monitoring in real time. All processes and the parts currently in production can be monitored on screens. The costs, time, and quality of the entire production chain can be accessed digitally at any time and from any location.

Automated cutting and bending systems digitally networked with an overarching software architecture that guides sheet metal parts on the optimal path through the individual process steps: from the incoming order data, to the programming of the cutting and bending plans and the best possible allocation to the available capacities of the integrated machine systems, all the way through to the delivery of the finished sheet metal products. In the whole process, sensors measure each step and thus enable monitoring in real time. All processes and the parts currently in production can be monitored on screens. The costs, time, and quality of the entire production chain can be accessed digitally at any time and from any location.

This vision of the smart factory is now becoming a reality. With its new Experience Center near Chicago, Bystronic is building the future of sheet metal processing. In the village of Hoffman Estates (Illinois) a new location is being constructed on an area of 15,131 square meters (162,875 square feet). The new building will include an advanced showroom of 2800 square meters (30,138 square feet). From the summer of 2019, here, just a few kilometers from its existing subsidiary in Elgin, Bystronic will display its entire range of sheet metal processing solutions: the latest technologies for laser cutting, integrated automation and storage solutions, flexible bending systems, tube and profile processing solutions, a software landscape that covers the entire sheet metal processing chain, smart services, and customized live demonstrations for customers.

Groundbreaking ceremony for the smart factory

The management of Bystronic welcomed numerous guests and representatives of the press to the official groundbreaking ceremony in Hoffman Estates on September 18, 2018. The event was also attended by Bystronic CEO Alex Waser. “In our new Experience Center, visitors will be able to gain a tangible insight into how modern sheet metal manufacturing can be digitally networked and fully automated,” Alex Waser explained. “During live demonstrations, Bystronic will show how throughput times and production costs can be reduced in a targeted manner within a smart factory while simultaneously ensuring that all available machine resources are used in the best possible way.”

In addition to customer-oriented live demonstrations, Bystronic will also offer software and hardware training courses in the new Experience Center. Customers will thus be able to benefit from the leading technology provider’s extensive know-how. “We offer the complete end-to-end solution comprising technology and services,” Alex Waser emphasized. Due to the increasing trend towards automation and digital networking, the demand of many customers for customized training and consulting by technology experts is growing.

The Experience Center will also serve as the new hub for Bystronic US business operations. Beside the showroom this hub will include sales, service, spare parts, the refurbishing of used machines and a modern assembly area for new laser cutting and automation systems.

Customer proximity and international growth

With the close proximity of the new Experience Center to Chicago, Bystronic is focusing on the hub of the North American market for sheet metal processing. Many metal processing companies supply their customers from here. In addition, many large corporations are based in Illinois and the neighboring states. And the close vicinity to the Chicago O’Hare International Airport ensures that the Experience Center is easily accessible to visitors from America and around the world.

With the construction of the new Experience Center, Bystronic is resolutely driving forward its ongoing growth strategy. Investments in the well-established global production, sales, and service infrastructure will strengthen the presence and anchoring of Bystronic’s technology and service portfolio in growth markets. In addition to North America, the focus also lies on Europe, China, and Southeast Asia. With the opening of the new center in the US in 2019, Bystronic will have a total of 20 Experience Centers worldwide, in which customers can experience state-of-the-art manufacturing systems, software, and services first hand.

About Bystronic

Bystronic is a leading global provider of high-quality solutions for the sheet metal processing business. The focus lies on the automation of the complete material and data flow of the cutting and bending process chain. Bystronic’s portfolio includes laser cutting systems, press brakes, and associated automation and software solutions. Comprehensive services round off the portfolio. The company headquarters are located in Niederönz (Switzerland). Three additional development and production locations are located in Gotha (Germany), in Tianjin (China), and in Shenzhen (China). Bystronic is actively represented by its sales and service subsidiaries in more than 30 countries and has agents in numerous other countries. As a reliable partner, Bystronic stands for high-performance innovations, local expertise, and service excellence. Since 1994 Bystronic has been a part of the Swiss industrial holding company Conzzeta. In 2017, with more than 2400 employees, Bystronic achieved a revenue of 774 million euro.