Attendees at the International Manufacturing Technology Show (IMTS) 2018 will experience the most powerful machining software from CNC Software, Inc. to date, Mastercam 2019. IMTS is a premiere manufacturing conference held every even-numbered year in Chicago, attracting an international attendance of more than 115,000 people.

CNC Software is a software company headquartered in Tolland, Connecticut, developing manufacturing solutions and the world’s most widely used CAD/CAM software, Mastercam. This year, visitors can investigate the latest functionality of Mastercam at the CNC Software / Mastercam booth (# 133340) in McCormick Place, September 10–15.

Mastercam 2019 helps increases machining productivity and reduces overall production costs with new 2D through multiaxis milling automation features, CAD and model preparation improvements, expanded 3D tooling, Accelerated Finishing™, and powerful turning and Mill-Turn enhancements.

CNC Programming

Mastercam 2019 continues to increase productivity and programming efficiency, while reducing overall production costs with a series of automated 2D through 5-axis toolpath improvements. Re-engineered chamfering and holemaking strategies, plus the new multiaxis deburring provide new levels of time-saving automation and simplicity. New milling toolpath strategies, like the highspeed Equal Scallop toolpath, offers both machining performance and surface finish improvements. The new release includes additional support for the Sandvik Coromant PrimeTurning™ method, enhanced grooving, bar feed, and other features for turning and mill-turn applications, plus new lathe and Swiss-style machine support.

Job Preparation and Setup

Mastercam 2019 increases efficiency and reduces job setup time and the preparation needed for part machining and programming. This includes enhanced CAD functionality and 3D model import support, improved part preparation and fixture setup tools, additional PowerSurface capabilities, and expanded support for Model-Based Definition (MBD).

Tool Support

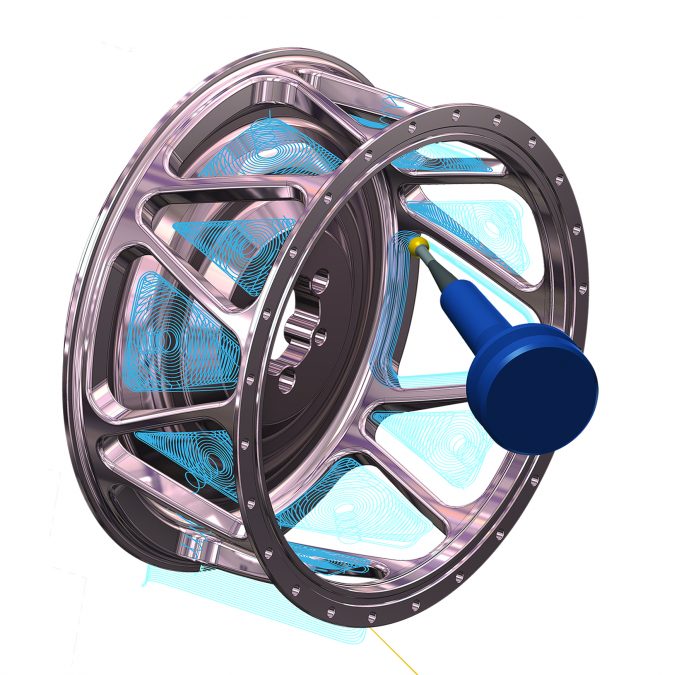

Mastercam 2019’s expanded digital tool library capability delivers accurate, 3D tool assembly models, provides access to the latest cutting tool technology, and updates for Sandvik Coromant CoroPlus and MachiningCloud platforms. Mastercam 2019 also expands Accelerated Finishing with support for taper and lens style tools aimed at 75% cycle time improvement for finishing operations with superior surface finish quality.

Validation

With improvements to toolpath and machine simulation, toolpath graphics, and other verification and analysis tools, Mastercam 2019 provides greater programming assurance and allows for better, more informed decisions before a job is run. These improvements include support for block drilling multiple holes simultaneously and better axis control in simulation, allowing you to easily check machine limits or collision checking.

Job Management and Documentation

Mastercam 2019 also improves job documentation and management, while helping to address quality and certification initiatives. New toolpath visualization capabilities and section view tools, improvements to view and setup sheets, and a wide array of system level enhancements improve efficiency in managing job workflow, as well as providing better tools for process documentation.

About Mastercam

Developed by CNC Software, Inc., Mastercam is Windows®-based CAD/CAM software for 2- through 5-axis routing, milling and turning, 2- and 4-axis wire EDM, 2D and 3D design, surface and solid modeling, and Swiss machining. Privately owned and founded in 1983, CNC Software provides CAD/CAM solutions to more than 250,000 installations in 75 countries in industries including moldmaking, prototyping, automotive, medical, aerospace, consumer products, and much more.