New REGO-FIX Through-Coolant System for Swiss-Style Machines

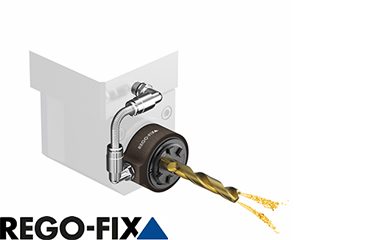

REGO-FIX has introduced a new addition to its line of reCool® retrofittable coolant-through systems. The reCool RCR/ERM not only provides all the benefits of reCool technology to Swiss-style machines, but also allows the use of emulsion or pure oil coolants.

Like its companion system, the new reCool RCR/ERM cost-effectively converts existing flood-cooled driven tools with ERM mini threads to through-tool-coolant capable in as little as two minutes. The system gets coolant to the cutting edge much more effectively than do spray piping or nozzles, and thus easily removes heat from the cutting zone and contributes to better surface finishes, longer tool life, improved chip control and increased productivity.

The reCool Mini accommodates standard speeds up to 12,000 rpm and coolant pressures up to 1,450 PSI/100 bar (2,150 PSI/150 bar optional).

REGO-FIX will display the new technology at IMTS 2016 in booth W-2239. They will also showcase all-in-one conversion packages for its popular intRlox® slip proof mini clamping nut system and Rigid Holders for high-security toolholding in high-cutting force applications.

About REGO-FIX

With U.S. headquarters in Indianapolis, Indiana, REGO-FIX, inventor of the original ER collet system, is a world leader in the manufacture of Swiss precision tooling.

We work for you. Exclusively the production factors of our customers determine what our products must do: enduring premium quality, the fastest possible availability from stores

and customer service on site around the world.

Furthermore, we consider and value our environment. Social values characterize our everyday work, the manner in which we deal with our customers and employees as well as our commercial partners. With the expansion of our head office we also pursued new construction approaches in order to reduce or entirely negate the environmental impact of our operations.

For more information on REGO-FIX, visit the company’s website at www.rego-fix.com.