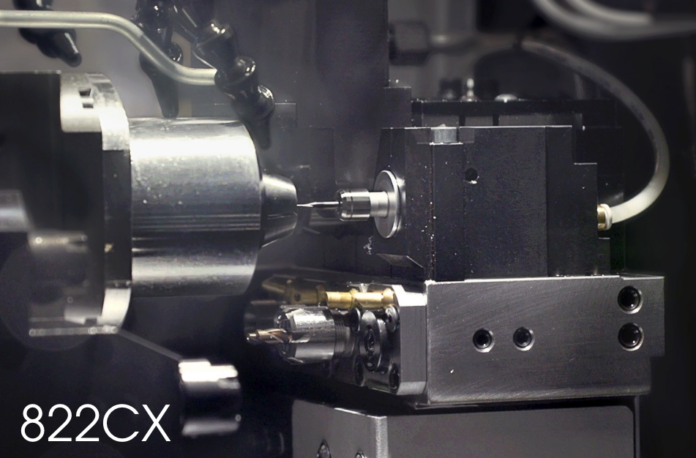

Air Turbine Technology Inc., the leading manufacturer of revolutionary high-speed turbine spindles, introduces a ground-breaking new series of Air Turbine Live Tools®, including its 822CX and 825CX. This series brings unprecedented reliability at governed cutting speeds of 60,000 to 80,000 RPM at a fraction of the cost compared to conventional live tools and spindles.

By automatically adjusting airflow CFM volume to match the cutting load, the patented double turbine-driven mechanism in Air Turbine Live Tools® assures consistent high-rated speed during the cutting process and enables 6 to 10 X faster production cycles on any lathe.

This governed mechanism eliminates the challenges posed by nominal high-speed products which drop speed in cut on the toolpath. The lack of consistent high speed causes tool breakage and sub-optimal or inconsistent finished surface quality. By contrast, Air Turbine Live Tools® optimize small tool performance and enhance surface finish while cutting down production time exponentially.

Air Turbine Live Tools® direct drive system has just two moving parts and air-cooled precision bearings. The system does not generate heat or burnout like electro-spindles. In continuous 24/7 micro-machining operations, Air Turbine Live Tools® stay cool, maintain zero thermal growth, and deliver consistent 2-micron accuracy.

Installation is simple. Users can connect dry 90 psi (6.2 bar) compressed air and activate with an M Code or Solenoid. This is unlike traditional technologies with complex hour-long set-ups involving control boxes, wiring, and lubrication.

The 822CX and 825CX dimensions fit most holders. Air Turbine Live Tools® are operational within moments of being placed into a tool holder. Smaller side air feed units are also available for added flexibility in machines with tight dimensions, such as Cincom and Star.

Everything, including a filter extractor and hose, is included in a case with Air Turbine Live Tools®. Ultra Precision ER8 and ER11 UP Rego-Fix ER collet systems are standard on Air Turbine Live Tools® and h7 bodies assure precision.

Rather than changing the speed of the traditional electro-spindle for different cutting tools, the operator of fixed high-speed Air Turbine Live Tools® simply adjusts the rate of advance programmed to achieve the desired Surface Feed per Minute for any tool. No lengthy adjustment in a control box is needed.

Air Turbine Live Tools® are ideal for applications in industries where production pressure, precision, and finish quality are critical, such as electronics, medical, optical, implant, and food production. With its sealed design, this oil-free live tool is ideal for cleanrooms, emitting no oil mist that could contaminate parts or the workspace, and remaining unaffected by machine coolant.

Most notably the 822CX and 825CX at 60,000 RPM and 80,000 RPM change the economics of lathe operations with small tools combining affordability with material reduction in cost per part produced. Air Turbine Live Tools® also require no maintenance, eliminating downtime, and operate without lubrication and associated costs.

Most notably the 822CX and 825CX at 60,000 RPM and 80,000 RPM change the economics of lathe operations with small tools combining affordability with material reduction in cost per part produced. Air Turbine Live Tools® also require no maintenance, eliminating downtime, and operate without lubrication and associated costs.

Setting a new benchmark in affordability, these tools are priced at just one-third or less of the cost of traditional live tools.

The 822CX and 825CX are best sellers in an extensive range of Air Turbine Live Tools® available with Outside Diameters from 19.5 mm to 40 mm to fit tool holders on all types of lathes. At fixed governed speeds from 40,000 to 80,000 RPM, power ratings are available from 0.15 HP (0.11 kW) in the mini 800 Series to 0.8 HP (0.6 kW) in larger units.

The revolutionary 822CX and 825CX were developed with input from the Swiss industry leader, Tornos of Moutier, Switzerland, the respected pioneer in sliding head lathe manufacturing for over a century.

The company’s expertise continues to be applied to provide innovative high-speed solutions for the manufacturing industry across the world.

About Air Turbine Technology Inc.

Air Turbine Technology Inc. since 1988 has invented, patented, and proven a range of revolutionary high-speed spindles, live tools, motor mounts, and hand tools. Air Turbine Tools, Motors, and Spindles® are high-speed pneumatic tools used by manufacturers for cutting, grinding, engraving, drilling, or finishing materials in industrial processes, delivering superior performance in applications that demand high-speed, precision, and reliability at 25,000 to 90,000 RPM with power to 1.4HP. This new generation of products increases airflow volume to the turbine to match cutting load, ensuring consistent high speed without sacrificing power.

Air Turbine Spindles and Motors® operate reliably without generating heat to affect precision at 2 micron and have no duty cycle limitations.