The CERATIZIT UP2DATE catalog is now available, showcasing the latest product developments and advancements for the cutting tool industry. Designed to help customers optimize machining performance, extend tool life, and maximize production efficiency, this edition features tooling solutions tailored to meet intricate milling and micromachining operations. Included in the spring 2025 UP2DATE edition are the MaxiMill – Slot-SNHX milling cutter, the MaxiMill – Tangent milling cutter, and the WTX – Micropilot micro drill.

“Customers come to us for more effective and productive cutting tools which we deliver with support and technical expertise,” says Troy Wilt, Managing Director of CERATIZIT USA. “Applying our technical expertise in the field often leads to new and better solutions that work across multiple industry sectors.”

Groove milling made easy

The MaxiMill – Slot-SNHX is a robust side and face milling cutter system that is engineered for exceptional performance across a range of materials, including steel, cast iron, and aluminum. The innovative tool is designed to deliver soft cuts while effectively avoiding interfering contours, making it an ideal solution for diverse milling applications.

The MaxiMill – Slot-SNHX features trouble-free contours on the face side and sufficient axial freedom of movement that ensure smooth machining — even in hard-to-reach areas. Thanks to precision-ground indexable inserts, machinists can expect a flat groove base that ensures perfect surfaces from the very first cut. The system is also equipped with an internal coolant supply up to a diameter of 200 mm, which minimizes chip jamming and further boosts efficiency.

The MaxiMill – Slot-SNHX is available in three models to offer the most universal connection on the market. These slip-on milling cutters offer diameter ranges from 80mm to 200mm each of which include internal coolant supply, and multiple sized cutting widths. The screw-in milling cutter also provides an internal coolant supply on diameters of 50mm, 63mm, and 80mm and cutting widths of 6mm and 8mm. The milling cutter with cylindrical shank and internal coolant supply is available to CERATIZIT customers in diameters of 50mm, 63mm, 80mm and 100mm as well as cutting widths of 6mm and 8mm.

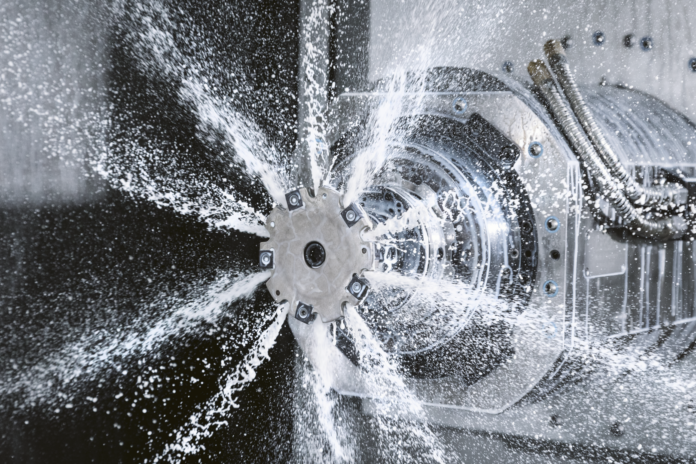

Better reach and pace

The MaxiMill – Tangent is CERATIZIT’s new tangential indexable milling cutter designed for machining hard-to-reach steel or cast iron components. Engineered to deliver stable and soft-cutting machining, it provides a uniform chamfer profile over the entire length of the cutting edge for maximum stability within a single system.

The MaxiMill – Tangent has indexable inserts optimized for machining ISO P and ISO K materials. Moreover, it features a maximum infeed depth of 8 mm for the -09 insert, while the larger model goes even further to 12 mm. The MaxiMill – Tangent includes universal -M50 and -F50 chip breakers, offering enhanced cutting-edge stability due to a reduced radial clearance angle.

Furthermore, there is an integrated face-cutting edge, which offers machining benefits, including uniform material removal that results in a smoother component surface. In addition, the cutting forces are distributed more evenly and reduce the load on both the tool and the machine.

The MaxiMill – Tangent is available in three mounting styles: shell mill, screw-in cutter, and straight shank. Cutter diameters range from 25mm to 125mm. The large and stable contact surfaces in the integrated carrier inserts carrier provide additional stability and reliability. Plus, compared to radial systems, tangential clamping provides extra space for significantly more indexable inserts on the milling cutter body, thus guaranteeing maximum cutting-edge density and efficiency. Inserts can be rotated, turned, and replaced quickly and easily to prevent any drop-offs in efficiency during tool changes.

A complete micro drill system

The WTX – Micropilot is an innovative micro drill used for spot drilling small components with intricate geometries. Working in tandem with CERATIZIT’s WTX – Micro, the pilot drill is small in stature and delivers big performance with exceptional accuracy and time-savings for micro-sized components.

The risk of micro-sized components becoming scrap is high. Several things can go wrong: drills run off, drill holes get crooked, tools break, and the workpiece itself can become damaged. With a special drill point angle of 160 degrees, the WTX – Micropilot guarantees maximum positioning accuracy and prevents wandering while drilling to achieve extreme precision within a single run. Since it is designed to co-drill with the WTX – Micro, the usual mirroring required for drilling inclined and curved surfaces with an inclination up to 50 is no longer necessary, saving time and tool changes.

Additionally, the WTX – Micropilot is coated in CERATIZIT’s innovative Dragonskin for optimum chip clearance and extended tool life. It also has spiral internal cooling channels to ensure maximum flow of cooling lubricant for improved surface finish.

About CERATIZIT USA, Inc.

Part of the CERATIZIT Group, CERATIZIT USA designs and manufactures high quality standard and custom tooling for the metalworking industry. CERATIZIT USA, LLC is a solutions and service provider for many different industry segments, including automotive, aerospace, and energy. With a highly specialized staff, expansive product portfolio and an International Traffic in Arms Regulations (ITAR) registration, CERATIZIT USA provides manufacturers with the complete application engineering, service and training support needed for maximum productivity and cost-effectiveness.