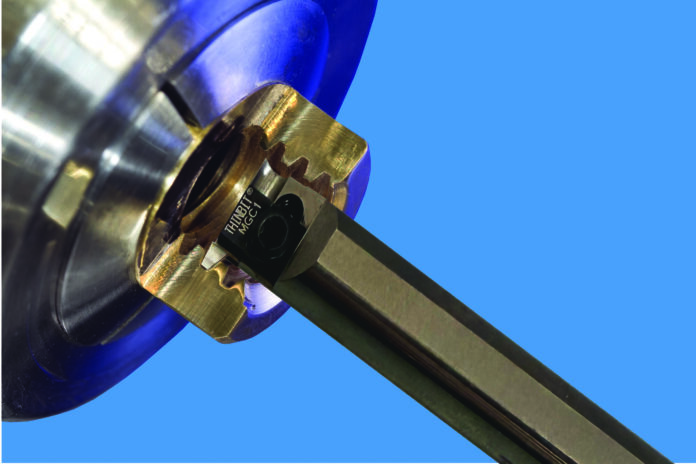

THINBIT ®, manufactured by Kaiser Tool Company, is pleased to announce the expansion of their MINI GROOVE ‘N TURN® line with ACME THREADING inserts.

MINI GROOVE ‘N TURN® ACME THREADING inserts are designed to cut thread sizes of 6 threads per inch and greater. Tools have geometry to cut standard 29° acme thread profiles. Inserts can be used to cut centralizing or stub profiles by overcutting. The inserts can be used for internal acme threads on parts with bore diameters of .325” and larger.

Available in sub-micron grain carbide grades for ferrous and non-ferrous materials either uncoated or with TiN, TiCN, TiAIN or diamond film coatings. MINI GROOVE ‘N TURN® ACME THREADING inserts can be used on conventional, Swiss and CNC machines.

Toolholders are available in round shank size 1/4”, 3/8”, 1/2” and 5/8” in steel, heavy metal and carbide. MINI GROOVE ‘N TURN® ACME THREADING inserts fit existing “MGT” series THINBIT® toolholders.

THINBIT® offers an extensive selection of 60º and ACME thread forms for both internal and external threading. Custom thread profiles with deliveries from 5 working days are available.

About Kaiser Tool Company

Kaiser Tool Company, Inc. is a world leader in the manufacturing of precision cutting tools for grooving, threading and boring. Our customers know and depend on us for our:

Quality Products,

Fast Delivery,

Superior Customer Service.

Kaiser Tool Company was founded in 1964 with the purpose of supplying small lathe cutting tools that were not available as standard, in-stock items. Today, our line of THINBIT® cutting tools includes more than 100,000 in-stock tools for grooving, threading, parting, boring and turning as well as custom tools.

In 1987 we started Laser Images® to provide our customers with laser engravings that are clean, consistent and perfect every time. Instruments, dials, wheels, scales, cutting tools and more, we can engrave virtually anything of any shape and size.