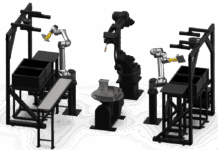

Serra Laser will introduce the LightBOT Robotic Laser Welding System at Fabtech 25. LightBOT uses Fanuc CRX co robots and the IPG LightWELD laser welders to produce a cost effective laser welding system that is very flexible. Less than 5 minutes is needed to switch the LightWELD from hand held to co robot mode or back. Retrofittable to any existing LightWELD or can be added new. All functions are controllable from the Fanuc controller and wire welding, fusion welding, spot-tack welding, and laser cleaning can be done. LightBOT can be purchased with or without a LightSAFE or LightCELL laser welding enclosure. The LightCELL can be used for hand LightWELDING or for production welding using the quick switch door – the welder can be outside the enclosure when loading and unloading parts. No knowledge of robot programming is needed with the Fanuc CRX. The Fanuc uses a unique horizontal timeline where the robots arms are moved by hand – a position or LightBOT Icon swiped up to the timeline to memorize the position or tell the robot what to do – such as fire the laser – and the process is followed until the weldment is done. Power can be changed on the fly or any welding condition can modified or called on the fly. For reference the IPG weld mode chart is used and the welder can also use his own preset welding conditions – just like you do by hand. The IPG LightWELD user interface runs directly on the Fanuc tablet. If a welder knows how to LightWELD by hand they can pick up how to weld with the LightBOT within a few hours of training that is done during the on site installation that is standard with the Fanuc LightBOT System. Adaptive Wire Feed Control is available on the Fanuc CRX and this means the welder does not have to try and coordinate wire speed with robot speed. Instead only robot speed is set and this controls the wire speed meaning perfect coordination or wire and motion are attained. For additive applications the ratio of wire to robot speed can be set making it easy to control wire deposition. In development with Fanuc and IPG since 2022 the LightBOT System is running at over 70 users worldwide with the 1st units delivered 2 years ago. Options include multi axis control and up to 2 coordinated axis can be added using Fanuc motors and drives. Turntables, linear rails, or tilt and rotate positioners can be added to the Fanuc system. Wire welding is a specialty of the LightBOT AP and more than one wire feeder can be “on line” at the same time – making switch over of wire type fast. The LightWIRE SERVO wire feeder – single or double, or the IPG wire feeder can be used with the LightBOT. Serra Laser has locations in Michigan, Texas, and California and is IPGs largest dealer for LightWELDs and a Fanuc Authorized Integrator specializing in robotic laser welding applications. We also manufacture the LightSAFE and LightCELL laser welding enclosures. On site installation and training is available with every Fanuc system. Fanuc was chosen as the co robot supplier because of Fanuc support and the 8 year maintenance free design of the Fanuc CRX co robots. The LightBOT system is a result of close collaboration with Fanuc and IPG Photonics and uses the IPG electronic trigger system. Depending on the LightWELD model and Fanuc CRX used a robotic laser welding system is attainable for under $100,000 – a price point never seen before for a laser welder made in the USA – IPG Photonics – combined with the world leader in robotics – Fanuc America. If a potential user already has a Fanuc CRX we can also add our LightBOT SW and HW and create a laser welding system. The LightBOT can be seen in Booth A6581 in the main machine hall at Fabtech 25.We will have two Fanuc CRX robots running the LightBOT System – the 30iA with a 74 inch reach ad the 10iAL with a 55 inch reach.

SUBSCRIBE to our Complimentary Publications: