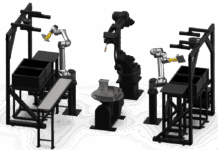

To help metal fabricators improve productivity, quality and workforce needs, ESAB has launched its new Tracfinder Rail and Tracfinder Wheel series of battery-powered welding tractors and unveiled its newly branded ROBBI™ Mobile cobot welding system. ROBBI is now available with the Aristo Edge 500R power source and RoboFeed Edge robotic wire feeder, which offer next-generation capabilities. Compared to manual welding, these automation solutions can typically increase output per operator by 70 to 100%.

“ROBBI Mobile cobots overcome traditional barriers to welding automation, especially among small- to medium-sized businesses,” says Dan Colvin, ESAB Vice President, North America Robotics & Digital Solutions. “They deploy quickly and easily, feature operator-friendly controls, require no robotic programing knowledge and are suitable for high-mix/low-volume and medium- to high-volume production runs. ESAB automation solutions enable fabricators and manufacturers to leverage the talents of existing staff, strengthen profitability and improve the operator’s working environment.”

Welding Cobots

ROBBI Mobile welding cobots feature a Universal Robots’ UR10e or UR 20e industrial robot arm and a Siegmund 32- x 48-in. or 5- x 10-ft. table. The ESAB Teach Tool uses a ‘no code’ or plain language program so users can effortlessly incorporate a multitude of functions that enhance performance and productivity.

“ROBBI offers the most intuitive operation of any welding cobot on the market, enabling fabricators to start producing more parts almost immediately,” adds ESAB’s Colvin.

ROBBI is now available with the Aristo Edge 500R power source and RoboFeed Edge robotic wire feeder. Aristo Edge 500R ensures precise arc starts and enhanced stability across four advanced WeldModes — THIN, ROOT, ROOT Pipe and SPEED — as well as an Advanced Pulse WeldMode. All WeldModes enhance arc stability, offer more control at faster travel speeds and reduce spatter for less post-weld clean-up. The Aristo Edge platform also empowers independent development of synergic lines.

Rail and Wheel Option Tractors

Tracfinder Rail is designed for welding in all positions using high-stability rails and a rack-and-pinion transmission to prevent slippage at speeds up to 71 in./min (180 cm/min). Its unique joint-teaching software enables users to create a weld path with up to 50 points.

Tracfinder Wheel, the most versatile autonomous welding tractor on the market, features a magnetic base with 62 lbs. (28 kg) of magnetic force that enables it to operate in all welding positions at speeds up to 79 in./min (200 cm/min), including vertical up and down, overhead and on inside and outside diameters. New tracking software adjusts the Tracfinder Wheel’s trajectory based on torch position, eliminating the need for rails and minimizing setup time. Dual motorization (independent left/right control) and 4-wheel drive ensure optimal traction and stability in all welding positions. The optional remote control lets users adjust direction while the tractor is moving, much like a remote controlled car.

Designed for maximum flexibility, Tracfinder tractors feature a common operator interface that is available with Standard, Advanced and Advanced+ control packages. The two Advanced packages feature a remote control interface for operations up to 66 ft. (20 m) away, as well as advanced software. The Advanced+ package also features a communication module for two-way communication with the Aristo® Edge 500R power source and RobustFeed Edge wire feeder; otherwise, Tracfinder works with any brand of welding power source.

The Tracfinder advanced controllers enable users to save up to 30 jobs, storing programs for tractor parameters that include weld speed and length, delays, repetitions, stitch welding, back-step welding, three standard weaving patterns, the ability to customize the weave dwell time, width and speed, and a special multi-axis weaving function that combines horizontal and vertical weaving. Because all systems feature a common central control base and components, users can start out with the Standard control and upgrade to an Advanced or Advanced+ control.

By making continuous welds, Tracfinder tractors reduce rework associated with start/stop defects. In applications where end-users expect uniform weld bead profile and penetration, mechanized tractors deliver consistency without the cost or complexity of automation. They also reduce operator stress by reducing fume and UV radiation exposure, as well as reduce welding in uncomfortable positions.

Applications include those associated with shipbuilding, offshore yards, structural steel, tank and vessel, pipeline, wind tower, repair and maintenance (especially hardfacing) and high-volume fabrication. Operating time for the carriage battery is between 10 to 20 hours, enabling the tractor to run for an entire shift before swapping out the battery, which is a standard Li-ion 18V power tool battery.

For conventional MIG and pulsed MIG processes, ROBBI pairs with the Aristo 500ix power source and RobustFeed U82 wire feeder, which feature pre-programmed synergic lines for common welding alloys.

Contact your ESAB representative or visit ESAB’s website to learn more about ESAB’s full portfolio of automated and mechanized solutions.

About ESAB

For more than 120 years, ESAB has been a world leader in fabrication technology. Our distinctive portfolio of fabrication solutions encompasses more than 40 of the world’s most trusted brands for welding and cutting equipment, automation, robotics, fabrication