- 95% of US industrial businesses plan to introduce new automation within the next three years

- Federal incentives and reshoring are accelerating factory automation plans

- Companies are turning to automation to fill labor gaps and improve job quality

- High upfront costs and skills shortages are pushing demand for leasing and robots-as-a-service

Nearly every US industrial business (95%) plans to introduce new automation within the next three years, signaling a major shift in how American industry operates, according to new research commissioned by RobCo. The findings come from the RobCo Automation Readiness Index, a survey of 400 US business leaders in sectors including manufacturing, construction, engineering, and healthcare, conducted by Sapio Research. The data show US companies accelerating automation of back-office and production processes to boost output, secure supply chains, and support a renewed push for domestic manufacturing.

While only one-third of companies said they were currently using robots, more than half (54%) are testing or planning to use them, indicating that robotics will likely play a major role in America’s new wave of automation.

Most companies said that new federal incentives to boost manufacturing, including new grants and tax incentives, were among the influences behind the drive to adopt the technology (73%), with 61% saying that onshoring or reshoring of production was a factor driving their automation plans.

Automation is widespread and adoption is accelerating

The research found that the automation revolution is well underway. Nearly half of businesses (47%) are already using some form of AI powered automation, and 94% have at least partly integrated their physical and digital systems, connecting factory machines to computers for tasks like monitoring production.

It’s a trend that’s set to accelerate, with three-quarters (76%) of companies saying they’re very likely to introduce new automation in the next three years. Among companies already using automation, 53% report increased productivity and 52% report significant time savings. More than half (52%) say automation has reduced waste, and 50% report improvements in resource efficiency.

Workforce shifts are driving use of the technology

Geopolitical and economic upheavals are transforming US industry. America is embarking on a once-in-a-generation push to expand domestic production, but Deloitte warns of a major bottleneck: While 3.8 million industrial jobs will be needed to meet demand, the country is likely to face a shortfall of 1.9 million workers. Automation might be the answer to the lack of workers: Businesses see automation as a way to improve operational efficiency (57%), enhance data accuracy and reporting (50%), and reduce manual errors (49%).

Automation as an ally for human workers

Robots are taking on repetitive and dangerous tasks, freeing employees for higher-value work. Research shows growing acceptance: 58% of employees and 55% of unions are positive about automation. Companies are already seeing results, with 43% reporting lighter workloads, higher productivity, and improved morale.

Driving adoption are clear human-focused goals: boosting satisfaction (42%), addressing staff shortages (37%), reducing errors (49%), and cutting time on repetitive tasks (47%). Even non-automated sectors see potential gains in efficiency and reduced reliance on skilled labor. The message is clear: automation empowers people, rather than replaces them. But obstacles remain as funding models are outdated.

Almost half (48%) say that high initial investment is holding them back, with traditional funding models requiring high investment in physical robotics assets and third-party vendors for integration and maintenance.

Almost a third (27%) cited workforce challenges, including a lack of skilled staff capable of helping integrate automated technology, as hindering adoption.

Many are seeking new flexible and easy to scale funding models to adopt automated robotic models, with leasing (50%), federal state grant (45%) and robot-as-a-service (RaaS) models among the most popular alternative funding models. Models such as RaaS tie payments to business outcomes and bundle maintenance, integration, and software updates into a single, predictable fee.

The findings point to a clear shift away from large, one-off capital projects toward subscription-style models like RobCo’s robots-as-a-service offering.

“Modern robot-as-a-service models offer companies an attractive opportunity to significantly lower the barriers to entry into automation. Instead of high initial investments, companies pay predictable monthly or usage-based fees, thus avoiding long-term risks,” says Roman Hölzl, CEO and co-founder of RobCo.

“The model allows new technologies to be tested flexibly without tying up large sums of money, while providers take care of service, repairs and software updates. In turn, downtime is reduced, operational reliability increases and automation projects can be implemented more quickly – often without lengthy internal approval processes. At the same time, the ongoing shortage of skilled workers continues to intensify, making automation not a hurdle but a key part of the solution. Automating the ordinary today enables skilled workers to focus on the extraordinary.”

About RobCo

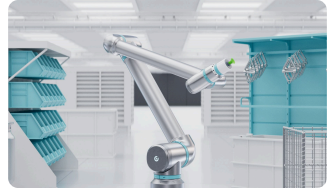

Founded in 2020 out of the Technical University of Munich, RobCo is on a mission to make industrial automation more accessible, affordable, and adaptable. Its patented modular hardware kit, combined with the RobCo Studio no-code software platform, allows industrial companies of all sizes to automate repetitive and dangerous tasks quickly and with unmatched flexibility. Whether it’s machine tending, palletizing, dispensing, or welding, RobCo’s modular robot kits provide versatile end-to-end solutions that are simple to deploy and manage remotely – without heavy upfront investment or specialist expertise. With offices in Munich and San Francisco and robots already in operation worldwide, RobCo is supercharging a new generation of industrial companies to reduce costs, boost productivity, and compete on a global stage.