A next-generation laser scanner designed for use on coordinate measuring machines (CMMs) has been launched by LK Metrology, a global leader in precision metrology solutions. Building on the success of the L100, the new L100NX introduces advanced blue laser technology, delivering superior scanning performance, accuracy and user experience.

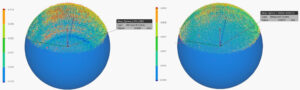

Unlike its predecessor, which utilized red laser light, the new scanner employs a 450-nanometre blue light laser that significantly reduces noise in scan data, resulting in cleaner and more reliable measurements. This advance is particularly beneficial for high-precision applications where data integrity is critical, such as in the aerospace and automotive sectors.

The L100NX combines speed and precision with a wide stripe width of 110 mm and a scanning rate of up to 530,000 points per second, making it ideal for inspecting large components productively. Its high accuracy ensures that even the most demanding inspection tasks may be handled with confidence.

At the heart of the L100NX is LK’s 4th-generation ESP (enhanced sensor performance) technology, which intelligently adjusts laser power for all of the 2,000 points on the laser line. This allows the scanner to measure multi-material assemblies and shiny surfaces seamlessly without surface preparation or other manual intervention, streamlining the inspection process and reducing operator workload.

At the heart of the L100NX is LK’s 4th-generation ESP (enhanced sensor performance) technology, which intelligently adjusts laser power for all of the 2,000 points on the laser line. This allows the scanner to measure multi-material assemblies and shiny surfaces seamlessly without surface preparation or other manual intervention, streamlining the inspection process and reducing operator workload.

To further enhance usability, the sensor features an integrated rotation adaptor, enabling optimal orientation of the scanner for inspecting complex part geometries. Additionally, an integrated FOV (field of view) projector visually displays the scanner’s coverage area directly onto the part, simplifying programming and setup.

The L100NX scanner kit comes in a protective casing that, in addition to the scanner itself, contains all necessary accessories and documentation required for operation and basic maintenance

Kristof Peeters, Product Manager for laser scanners at LK Metrology said, “The L100NX represents a major leap forward in laser scanning technology. By combining blue laser precision with intelligent sensor performance and user-friendly features, we’re delivering a solution that meets the evolving needs of modern manufacturing.

“The launch of the L100NX underscores LK Metrology’s commitment to developing innovative metrology equipment that empowers customers to achieve greater efficiency and accuracy in their inspection processes.”

About LK Metrology

LK Metrology is renowned for innovative metrology solutions and services. The company’s products, including coordinate measuring machines (CMM), portable measuring arms and metrology software, are used worldwide to control and improve the quality of manufactured components. Its precision technology underpins the process chain from design, development, production and assembly through to quality assurance in global industries such as automotive, aerospace, defence, motorsport, energy, medical and contract inspection.

Established in England in 1963, LK Metrology has an impressive heritage in metrology dating back to the birth of CMM technology. Founded by CMM pioneer Norman Key and his father-in-law Jim Lowther, LK Metrology is credited with many of the CMM industry’s firsts including the first bridge-type design, first OEM to integrate computers, first to use a touch trigger probe, first to develop inspection software, first to use all air bearings and granite guideways, first to use carbon fibre composite spindles, first to use microprocessor-controlled drive systems, first to produce a truly thermally stable CMM and first to produce a high-accuracy horizontal-spindle CMM.

In 2018, LK Metrology was relaunched as an independent CMM manufacturer after several years as a division of Nikon Metrology. Headquartered in the UK, LK’s CMM development and production are at the company’s facility in Castle Donington. Sales and support offices are located in the UK, North America, Belgium, France, Germany, Italy and China, supplemented by a worldwide distributor network.