The Mazak Ez Series comes to Canada for the Western Manufacturing Technology Show (WMTS) in Edmonton. In booth #1205, Mazak will feature its QT-Ez 12MSY Horizontal Turning Center with Multi-Tasking capability and the VC-Ez 20 Vertical Machining Center, both from the Kentucky-built series of machines that puts Mazak quality and reliability within reach for virtually any shop with productive, space-saving efficiency at an affordable price.

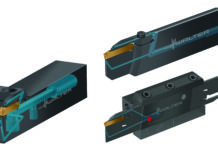

For Multi-Tasking part processing, the QT-Ez 12MSY accommodates rotating tools and features two turning spindles along with Y-axis functionality for efficient single-setup DONE IN ONE® processing of a wide range of parts. While the machine comes standard with a 12″ chuck, Mazak offers smaller 8″ and 10″ options.

Like all QT-Ez Series machines, the QT-Ez 12MSY is equipped with powerful, dependable integral motor headstocks, Hybrid MX linear roller guideways and pre-tensioned ball screws supported at both ends for reliable, thermally stable and precise machine axis movement. A new bed casting design provides outstanding rigidity, as well as streamlined chip flow to help eliminate chip accumulation. For ease of integration, the machine incorporates a 200-230 volt power supply system.

Along with optional spindles, chuck sizes and tailstocks, the QT-Ez Series is available with a complete range of additional cost-effective and popular options. These include Mazak’s Automatic Tool Eye, chip conveyor, auto door, auto parts catcher and high-pressure coolant systems, all of which make it easy for shops to further improve productivity.

For vertical machining, Mazak’s VC-Ez 20’s rugged 40-taper spindle and space-saving design offer unprecedented performance and affordability with a full range of spindle, auto tool changer and chip/coolant management options. The cost-effective, highly configurable machine meets many production facility needs with a compact, space-saving design.

Enhanced operator ergonomics and a generous work area ease the loading and unloading of workpieces and tools, while an extremely fast rapid traverse rate of 1,654 ipm (42 m/min) in the X, Y and Z axes enables higher throughput. A 25 hp (18.64 kW) 12,000 rpm (standard) or versatile 29.5 hp (22 kW) 15,000 rpm (optional) spindle offers 81.13 ft-lb (110 Nm) of torque for additional production versatility.

All VC-Ez Series machines sport C-frame designs with X and Y axis motion via moving the table and saddle. For rigidity and repeatable part precision, guideway systems use Mazak’s Hybrid MX linear roller guide systems, and dual lagged pre-tensioned ball screws ensure precise axis movement. For increased maintenance free operation, the auger-type chip removal systems provide an economical solution, or for increased chip volume the addition of an affordable hinge-type chip conveyor ships affixed to the machine to eliminate the cost of a second shipping pallet.

Mazak equips all its Ez Series machines with its Mazak MAZATROL SmoothEz CNC for ease of use and programming success. The control provides dual 800 MHz processors, 512 MB of RAM and a vibrant 15″ capacitive touch screen that includes a full keyboard and displays up to 60 lines of code. Within the control, G-code and Mazak MAZATROL Conversational programming languages support a full range of programming options, while the MAZATROL TWINS function enables use of Solid MAZATROL, Virtual Machining and Cutting Adviser through Smooth Cam Ai and centralized storage and file management through Smooth Project Manager.

In addition to its Kentucky-built Ez Series, WMTS attendees will be able explore the benefits of the Mazak MPower complete customer service and support program that comes with every Mazak machine.

About Mazak Corporation

Mazak Corporation is a leader in the design and manufacture of productive machine tool solutions. Committed to being a partner to customers with innovative technology, its world-class facility in Florence, Kentucky produces over 70 models of turning centers, Multi-Tasking machines and vertical machining centers, including 5-axis models, HYBRID Additive processing machines and Swiss Turning Machines. Continuously investing in manufacturing technology allows the Mazak iSMART Factory™ to be the most advanced and efficient in the industry, providing high-quality and reliable products. Mazak maintains eight Technology Centers across North America to provide local hands-on applications, service and sales support to customers.