The strength, durability, and overall performance of metal parts are shaped not only by their chemical composition but by how they are processed. Heat treatment is one of the most critical steps in metallurgy, transforming the microstructure of steel and alloys to achieve specific mechanical properties such as hardness, ductility, and toughness.

Three of the most widely used heat-treating processes—hardening, annealing, and tempering—rely on precision furnace technology to deliver repeatable, high-quality results.

Hardening: Maximizing Wear Resistance

Hardening: Maximizing Wear Resistance

The Process

Hardening heats steel or alloy components above their critical temperature and then rapidly quenches them. This locks carbon within the microstructure, resulting in a harder, more wear-resistant material.

Furnace Types

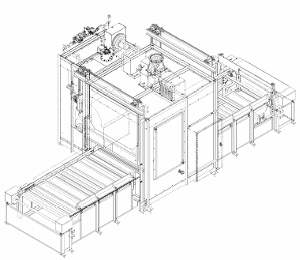

- Batch Integral Quench (IQ) Furnaces – Ideal for flexible workloads, offering precise heating and seamless integration with quench systems.

- Continuous Quench Furnaces – Designed for high-volume operations needing consistent performance and efficiency.

Key Benefits

- Uniform heating for reliable hardness

- Suitable for small batches or full-scale production

- Engineered for integration into automated heat-treating lines

Annealing: Enhancing Ductility and Stress Relief

Annealing: Enhancing Ductility and Stress Relief

The Process

Annealing heats metal to a controlled temperature and cools it slowly to relieve internal stresses, restore ductility, and improve machinability—making the material easier to form and process.

Furnace Types

- Box Furnaces – Excellent uniformity and ideal for smaller loads or specialty annealing cycles.

- Car Bottom Furnaces – Designed for heavy or oversized workpieces, with rail-mounted hearths for simplified loading and handling.

Key Benefits

- Exceptional temperature control for consistent stress relief

- Scalable for both small components and large fabrications

- Robust construction for long operational life

Tempering: Balancing Hardness with Toughness

The Process

After quenching, hardened steel can become brittle. Tempering reheats the material to a lower temperature to relieve stresses and create the correct balance between hardness and toughness—ensuring components can withstand demanding service conditions without fracturing.

Furnace Types

- Batch Temper Furnaces – Provide precise sub-critical heat to fine-tune mechanical properties.

- Continuous Temper Lines – Optimized for high-production facilities requiring consistent, efficient throughput.

Key Benefits

- Accurate temperature control for predictable results

- Reduced brittleness in hardened components

- Configurable to meet a wide range of metallurgical specifications

Final Thoughts

Hardening, annealing, and tempering form the foundation of modern metal processing. With the right furnace technology, manufacturers can achieve the exact combination of hardness, ductility, and toughness required for their applications.

Why Choose ITS Furnaces?

International Thermal Systems (ITS) engineers advanced, high-performance furnaces designed to meet the rigorous demands of today’s metalworking and heat-treating industries. Our product range includes batch IQ furnaces, car bottom systems, continuous lines, tempering equipment, and fully engineered custom solutions.

Our furnaces deliver:

- Energy Efficiency – Advanced insulation and optimized heating technology that reduce operating costs.

- Process Repeatability – Consistent, cycle-to-cycle performance for dependable quality.

- Customization – Systems tailored to specific metallurgical requirements and production goals.

- Global Support – Installation, training, maintenance, spare parts, and retrofit services—even for equipment built by other manufacturers.

For manufacturers who require precision, reliability, and long-term performance, ITS furnaces provide the trusted technology foundation for the future of heat treatment.

Whether you need the precision of a batch furnace, the throughput of a continuous line, or the rugged handling of a car bottom furnace, ITS delivers the engineering expertise to keep your steel operations competitive in a global market.

International Thermal Systems

International Thermal Systems (ITS) is a global leader in designing and manufacturing industrial ovens, washers, and furnaces. With a commitment to innovation and customer success, ITS provides tailored thermal-processing solutions for a wide range of industries including aerospace, automotive, metal packaging, and more.

https://www.internationalthermalsystems.com/