In this insightful edition of Industry Insights, Brian Self and William Strickland from Industrial Machinery Digest engage in an enlightening conversation with Al Dopf, the National Sales Manager for Hainbuch America. Al brings a wealth of knowledge and expertise to the table, discussing the cutting-edge workholding technology that Hainbuch offers. From the origins of the company in the 1950s to the innovative developments in collet chucks and ID mandrels, Al sheds light on how Hainbuch’s solutions cater to both OD and ID clamping, with a particular emphasis on their flexibility and efficiency. The discussion delves into the company’s groundbreaking hexagonal technology, its role in automated manufacturing, and how it integrates with Industry 4.0, offering insights into Hainbuch’s vision and contribution to the future of precision workholding.

Hainbuch’s Background and Innovations

Can you introduce yourself and your role at Hainbuch America?

I’m Al Dopf, the National Sales Manager for Hainbuch America. We specialize in workholding for OD and ID clamping, including collet chucks and ID mandrels, primarily for round parts ranging from six inches down to a few millimeters. We also work on specialized engineered products.

What is the history and key innovation of Hainbuch?

Hainbuch was founded in the 1950s and made a significant breakthrough in the late 70s by patenting the segmented collet chuck with vulcanization. This innovation allows for flexible and efficient clamping of parts, offering both ID and OD clamping with high adaptability and precision.

Transitioning from Hainbuch’s foundational innovations, let’s explore how their technology has evolved to meet modern manufacturing demands.

Technological Evolution and Industry 4.0 Integration

How has Hainbuch’s technology evolved, particularly with hexagonal technology?

After our original patent on the round collet chuck expired, we developed hexagonal technology. This approach increases surface contact between the chuck and the collet, resulting in up to 25% more clamping force. It’s especially effective in ID clamping and offers significant torque, enhancing our workholding capabilities.

What advancements have been made in workholding automation and data integration?

We’ve integrated automation and Industry 4.0 technologies into our workholding systems. This includes our IQ Chuck, a smart chuck with embedded sensors for measuring various parameters like spindle speed and clamping force. We also utilize the MT Connect protocol for data transfer, allowing for efficient, lights-out manufacturing.

With these technological advancements, Hainbuch not only enhances the efficiency of workholding but also paves the way for futuristic manufacturing practices.

Access to Hainbuch Products and Industry Trends

How can shops access Hainbuch’s products and integrate them into their operations?

Shops can access our products through regional managers, distributors, machine tool dealers, and OEMs. We offer flexible solutions that cater to different needs, allowing shops to start with basic setups and gradually integrate more advanced systems for various clamping requirements.

What trends do you see in the industry, and how is Hainbuch positioned for the future?

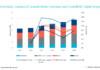

The industry is experiencing shifts with a focus on aerospace, defense, and medical sectors. Hainbuch is well-positioned to cater to these markets with our advanced workholding and automation solutions. While predicting exact future trends is challenging, we’re preparing for steady growth and adaptation to new demands.

As we dive deeper into the capabilities of Hainbuch’s technology, let’s understand how it uniquely serves various workshop sizes and the impact of the global economic situation.

Workholding Technology Benefits and Economic Impact

Workholding Technology Benefits and Economic Impact

What unique features does Hainbuch offer in its workholding technology?

Our workholding technology is highly flexible and efficient. We offer a system [centroteX] that allows for quick chuck changes, with repeatability within three microns. This includes adapting competitor chucks and our own, with a quick 15-degree turn and lock mechanism, significantly reducing downtime. Our technology also supports both small and large diameter clamping with various adaptations like ID mandrels and collet chucks.

Can you explain how Hainbuch’s technology supports lights-out manufacturing?

Our technology is conducive to lights-out manufacturing as it allows for robotic integration. Robots can change entire chucks or adapt clamping heads for different diameters, enabling continuous and unmanned operations. The integration of our IQ Chuck further enhances this, providing real-time data for predictive maintenance and process control.

How does Hainbuch’s technology contribute to Industry 4.0?

Our smart chuck technology, part of Industry 4.0, enables real-time data collection and transmission. This includes monitoring spindle speed, clamping force, part diameter, temperature, and confirmation. The data is transferred wirelessly, which is crucial for rotating chucks, and can be integrated with machine monitoring systems for on-the-fly adjustments and predictive maintenance.

What are the benefits of Hainbuch’s technology for different sizes of workshops?

Our technology offers significant benefits for both small job shops and large production facilities. It provides flexibility in workholding, rapid changeovers, and enhanced productivity. This can be particularly valuable for shops that require frequent changes in workholding due to varying part sizes or production requirements.

How does the current global economic situation affect Hainbuch and the industry?

While the global economic situation presents challenges, certain sectors like aerospace, defense, and medical remain robust and are driving demand. Despite a general downturn in the machine tool industry, these sectors continue to invest in high-quality, precision manufacturing technology. Hainbuch, with its specialized focus and innovation in workholding, is well-positioned to cater to these industries.

Looking Ahead: Hainbuch’s Future Outlook

What future trends and business forecasts does Hainbuch anticipate?

Looking ahead, we anticipate a steady but cautious market environment. While we’ve experienced strong performance, we are preparing for potential flat growth in the coming year, given the global economic uncertainties. Our focus will continue to be on delivering high-quality, innovative workholding solutions tailored to the evolving needs of key sectors like aerospace and defense.

Conclusion

This discussion with Al Dopf from Hainbuch America not only highlights the company’s commitment to innovation in workholding technology but also sheds light on its adaptability to the changing landscape of manufacturing. With a keen eye on future trends and a strong foundation in technological advancements, Hainbuch is poised to continue its role as a key player in the precision manufacturing sector.