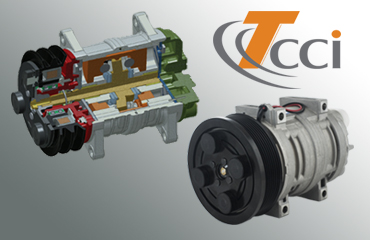

OEM compressor designs for both large and small busses provide new, more durable, compact solutions that provide the right displacement for each job

T/CCI Manufacturing, a world leader in compressor technology including reciprocating, swash plate, wobble plate, and variable compressor designs, is introducing two new compressors for the bus market in the United States and Canada.

The QPS 65 Swash Plate compressor provides the latest technology and design for buses, transport refrigeration vehicles and other applications that require large capacity displacement. The new, smaller design is tailored to align with industry trends in bus manufacturing, downsizing engine space and the ability to mount traditional compressors.

“The QPS65 is the direct result of industry demand in the market,” T/CCI President Richard Demirjian said. “We have applied 30 years of engineering expertise to develop a durable, lower cost compressor that provides a smoother, more comfortable ride. We have also allowed for more clutch configurations resulting in the ability to customize solutions for partners in the U.S., Canada and around the world.”

“The QPS65 is the direct result of industry demand in the market,” T/CCI President Richard Demirjian said. “We have applied 30 years of engineering expertise to develop a durable, lower cost compressor that provides a smoother, more comfortable ride. We have also allowed for more clutch configurations resulting in the ability to customize solutions for partners in the U.S., Canada and around the world.”

The QP25 is designed for school busses and smaller bus applications, providing a versatile, lower cost solution for new bus designs. The QP25 model provides higher capacity than the QP21 or enhanced 7H15 while being able to fit in the same mounting configurations. This provides an immediate, cost-effective solution to customers who need the higher capacity in extreme climatic conditions.

“The demand for buses worldwide is forecast to rise nearly five percent annually through 2021 and the need to provide our OEMs with customized solutions at an affordable cost is higher than ever. Both the QPS 65 and the QP25 are quality tested products that have undergone T/CCI’s rigorous validation processes to meet industry leading performance standards,” Director of Engineering Dick Ennis said.

More About the QPS 65

The QPS65’s compact and light packaging meets the needs of most new bus designs. The swash plate compressor is more durable, and the NVH is lower than reciprocating compressors, providing a smoother, more comfortable ride. There are two model configurations available for the QPS65 – one rotates clockwise and the other counterclockwise. This enables compressor mounting either on the engine or opposite the engine when space constraints do not allow the compressor to be engine mounted. T/CCI is the only manufacturer in the industry with this style of compressor in a counter clockwise rotation.

The QPS65 model can use both PAG or POE type oils depending on the customer’s needs which ensures compatibility with different system requirements.

Service and maintenance are enhanced with dual sight glasses to ensure compressor oil levels are maintained and shaft seal leakage is minimized by use of a superior “triple-lip shaft seal” unlike reciprocating compressors.

The QPS family also includes two smaller displacement models, the QPS43 and QPS55 which allows the customer to tailor their system designs more precisely than ever before.

More About the QP 25

The QP25 compressor has been fitted with a new design “4-eye” clutch with higher clamping force to accommodate the increased capacity of the QP25. The rubber dampening of the 4-eye armature provides smooth and quiet clutch engagements that ensures NVH (Noise, Vibration, Harshness) characteristics of the QP25 exceed customer expectations.

The QPS65 and QP25 are now available and being distributed to OEM dealers through the United States, Europe, South America and Asia.

About T/CCI Manufacturing

T/CCI is a world leader in compressor technology including reciprocating, swash plate, wobble plate, variable compressor and air brake compressor designs. We are an Original Equipment Manufacturer for trucking, off-highway, agriculture/construction, specialty vehicle and transport refrigeration markets. T/CCI is dedicated to a leadership role in the industry—investing resources through our engineering, testing and R & D labs including next generation refrigerants that reduce emissions. Our global footprint spans manufacturing locations in China, Argentina and the United States with warehousing, sales and engineering in Illinois, Texas, China, Argentina, Ireland, Germany and Spain. We are committed to providing customers with superior products at significantly better prices. We achieve this through our application expertise, global logistics, design thinking and product innovation. T/CCI is recognized and awarded Bronze SQEP certifications by Caterpillar at both Ningbo, China and Decatur, IL manufacturing facilities.