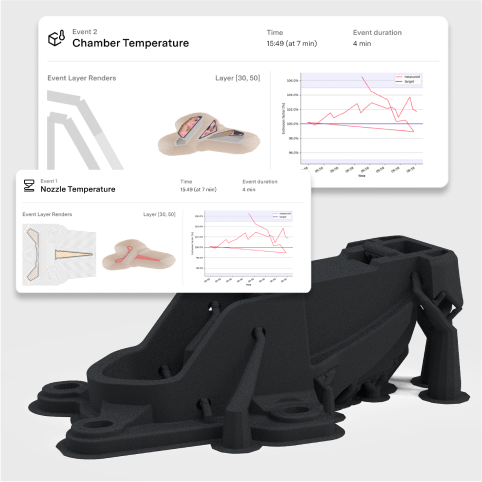

With the launch of the UltiMaker Factor 4, also came a new and exciting engineering 3D printing material: UltiMaker PPS CF.

As soon as you pick up a PPS CF part, you notice that this material is different. Give it a tap and its stiffness and density causes it to vibrate like metal. This metallic sound is also caused by the crystalline structure of PPS, where well-defined molecular arrangements contribute to its distinctive acoustic properties.

The different sound is a mere side effect of the amazing mechanical and thermal properties of PPS CF, which make it a great replacement for applications where you would have to use PEEK or even metal.

Extreme durability for industrial 3D printing with PPS CF

PPS CF is designed to withstand the harshest environments, offering exceptional chemical resistance, heat resistance, and dimensional stability. This high-performance material ensures that your industrial prototypes or functional end-use parts maintain their integrity over time, even under the most demanding conditions.

High-temperature precision with UltiMaker PPS CF

Specifically designed for use with the UltiMaker Factor 4 and print core HT, this advanced material provides the precision and reliability that today’s industrial demands require. As a semi-crystalline thermoplastic, PPS CF boasts a heat deflection temperature exceeding 230 °C post-printing, making it an exceptional choice for high-temperature applications.

An ideal substitute for parts made of metal or PEEK

UltiMaker PPS CF offers a compelling alternative to traditional materials like steel and aluminum. This means that you can harness the advantages of additive manufacturing, including lightweighting, reduced waste, and complete design freedom. The result is a versatile, cost-effective solution that doesn’t compromise on performance.