Three versions – endless application possibilities: FIPA GmbH (www.fipa.com) presents its new Cobot Smart Gripper CSG, which is specially designed for use with cobots. Three versions allow it to be used in different environments. The version with an internal electric vacuum pump is a technical evolution in terms of energy efficiency and paves the way for compressed air-free production.

Many industries automate processes in which only small loads are moved. Cobots or very small industrial robots with low payloads are often used here. Cobots enable direct collaboration with team members and can provide support, especially in monotonous and physically demanding work steps. They enable a space-saving and flexible working environment.

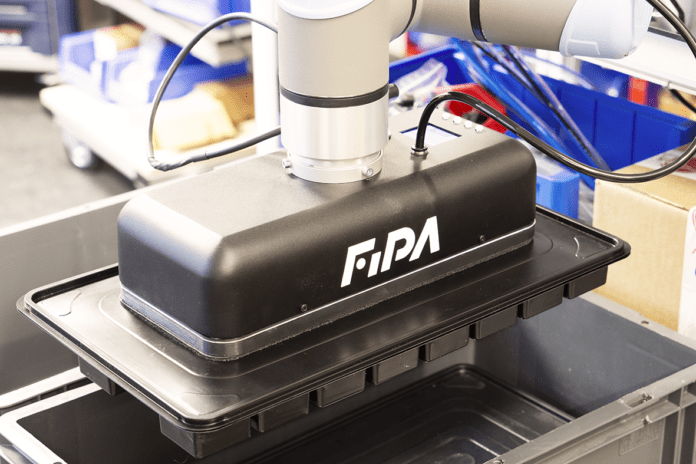

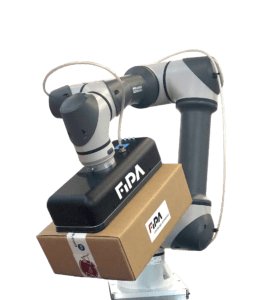

The use of cobots requires special grippers that must fulfil specific requirements, which are defined in ISO TS 15066, among others. Grippers for cobots and small industrial robots should be universally usable, quick to integrate and also as light as possible so as not to impair the payload of the robots too much. The latest innovation from FIPA is ideal for the fast and cost-efficient automation of processes, e.g. pick and place applications in the packaging industry, but also assembly tasks or a wide range of mechanical processes. Depending on the porosity of the material to be handled even with a payload of up to 35 kg. It is not without reason that the great advantage of the Cobot Smart Gripper CSG is already in its name: Smart stands for compactness and intelligent control – exactly what makes the Cobot Smart Gripper so special. Measuring just 300 x 130 mm, the gripper is very compact and space-saving, making it ideal for palletising cartons.

The use of cobots requires special grippers that must fulfil specific requirements, which are defined in ISO TS 15066, among others. Grippers for cobots and small industrial robots should be universally usable, quick to integrate and also as light as possible so as not to impair the payload of the robots too much. The latest innovation from FIPA is ideal for the fast and cost-efficient automation of processes, e.g. pick and place applications in the packaging industry, but also assembly tasks or a wide range of mechanical processes. Depending on the porosity of the material to be handled even with a payload of up to 35 kg. It is not without reason that the great advantage of the Cobot Smart Gripper CSG is already in its name: Smart stands for compactness and intelligent control – exactly what makes the Cobot Smart Gripper so special. Measuring just 300 x 130 mm, the gripper is very compact and space-saving, making it ideal for palletising cartons.

With three versions of the Cobot Smart Gripper, FIPA offers the right solution for every customer requirement: The fully electric version with an energy advantage of up to 90% compared to pneumatic grippers has an internal 24V vacuum pump. It is aimed at companies that strive for compressed air-free and therefore more energy-efficient production. The version with ejector operation has a multi-chamber ejector with blow-off function and scores with a very low weight of just 1,360 g. The simplest version without its own vacuum supply is suitable for use in processes with an existing infrastructure to generate the vacuum.

Thanks to the use of sealing foam the area gripper offers perfect adaptation to the respective product, even with rough or textured surfaces, and therefore a wide range of possible applications.

All versions have a built-in display to show the actual and target vacuum level. Process parameters can be set using the buttons next to the display. The flange connection to the cobot conforms to the ISO 9409-1 standard. Thanks to the user-friendly software the area gripper can be set up and operated intuitively.

Our Cobot Smart Gripper is compatible with all top cobot brands as well as wide range of industrial robots, regardless of the users’ levels of expertise or experience. The specific integration software is also available for selected cobots, enabling plug & play operation.

The Cobot Smart Gripper CSG at a glance:

• Solution-orientated: Three product versions enable variable use

• Low dead weight: Optimum utilisation of the robot‘s payload

• Cost-efficient: Increased efficiency thanks to intelligent control with energy-saving function

• Flexible use: Pick and Place in production and logistics

• Plug&Play: The gripper can be operated quickly and easily

• High compatibility: Compatible with a wide range of cobots and industrial robots