- Matrix Moon first in India to install 3d Systems EXT Titan Pellet 3D printer, pioneering manufacturing transformation

- Selected 3D Systems EXT 1070 Titan Pellet systems to deliver tremendous cost & time savings for breadth of applications, including sand casting, thermoforming, end parts production

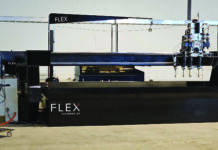

3D Systems (NYSE:DDD) announced Matrix Moon, an additive manufacturing-focused training center, and 3D Systems reseller located in India, purchased an EXT 1070 Titan Pellet 3D printer. Matrix Moon has chosen the configuration that includes the optional milling spindle tool head to enable hybrid additive and subtractive manufacturing processes on the same machine. By being the first to introduce this unique platform to India, Matrix Moon believes it will take a leading role in transforming manufacturing workflows while dramatically increasing the speed of innovation and reducing costs. Matrix Moon will employ the EXT Titan Pellet system to more efficiently, and cost-effectively deliver a broad range of applications for its customers including molds, tooling, and patterns for foundries and plastics manufacturers, as well as end-use parts in industries such as aerospace, automotive, HVAC, and consumer products. In addition to delivering prototypes and production parts for its customers, Matrix Moon intends to use its EXT 1070 Titan Pellet 3D printer to produce sample parts from its demo center. Prospective customers will have the opportunity to validate the printer’s capabilities before purchasing a machine for their facilities.

3D Systems’ EXT Titan Pellet systems are renowned for their ability to help manufacturers deliver products more efficiently at significantly lower costs as compared to traditional manufacturing methods. This is made possible by employing proprietary pellet extrusion technology which is up to 10x faster than filament printing with 10x lower material costs. These large-format 3D printers feature active chamber heating which allows for the use of glass- and carbon-filled high-temperature engineering materials such as ABS, PC, Nylons, PEI, and PEKK. With large print volumes, EXT Titan Pellet systems enable full-scale prototyping and end-use production in many applications where the use of additive technology was not previously possible. Additionally, 3D Systems’ extrusion printers enable 3D printing of large format tooling, molds, and patterns for a variety of foundry applications including sand casting. Matrix Moon believes the addition of its EXT 1070 Titan Pellet system will be transformative for India’s casting industry, which is recognized as the second largest in the world behind China.

Abhinav Garje, CEO, Matrix Moon Private Limited, said, “Today I am extremely delighted and filled with immense pride to announce that Matrix Moon is the only company in India to offer 3D Systems’ EXT Titan Pellet 3D printer. This cutting-edge global-grade technology is set to change the face of manufacturing in India. Imagine printing parts as tall as six feet and machining it in the same printer for your end-use production applications. This will now be possible with our latest and unique offering. With our continued focus on Skill India and Make-in-India missions, I believe that the EXT Titan Pellet 3D printer has the potential to transform assembly lines and how products are manufactured in India. Along with 3D Systems, we not only endeavor to augment the adoption of additive manufacturing in production but also to make India a global manufacturing hub with such pioneering technology. EXT Titan Pellet is a critical step in that direction.”

“I couldn’t be more excited that our partner, Matrix Moon, is the first to bring this industry-leading technology to India,” said Deelip Menezes, managing director, 3D Systems India. “Matrix Moon has demonstrated its understanding of the Indian manufacturing sector and is committed to advancing additive manufacturing in the most populous country on Earth. By choosing 3D Systems’ EXT Titan Pellet 3D printer, Matrix Moon is offering an unparalleled platform that can include pellet extrusion, filament extrusion, and a subtractive milling tool head on the same machine. Combining these additive and subtractive technologies along with pellet materials will allow Matrix Moon to address a greater breadth of applications for its customers and grow the number of EXT Titan Pellet systems in use in India to transform manufacturing.”

About 3D Systems

More than 35 years ago, 3D Systems brought the innovation of 3D printing to the manufacturing industry. Today, as the leading additive manufacturing solutions partner, we bring innovation, performance, and reliability to every interaction – empowering our customers to create products and business models never before possible. Thanks to our unique offering of hardware, software, materials, and services, each application-specific solution is powered by the expertise of our application engineers who collaborate with customers to transform how they deliver their products and services. 3D Systems’ solutions address a variety of advanced applications in healthcare and industrial markets such as medical and dental, aerospace & defense, automotive, and durable goods.