“Manufacturing is experiencing a dramatic increase in automation right now, we’ve really seen that in our custom-engineered business” said Chuck Milam, Kurt Workholding Sales Engineer. “Expanding the the DX lineup into a full range of hydraulically-actuated models helps make automation more accessible for small and large shops alike.”

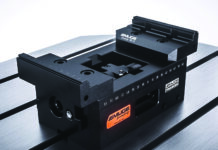

DXH vises have a new, premium one-piece body design now standard on all Kurt general-purpose vises. Designed using Finite Element Analysis, the new body has 30% less horizontal (push back) deflection than previous DX models. Vises are available in three sizes: DX4H, DX6H and DX8H and reverse models. DXH Hydraulic Vises have the same bed height and keyway to the stationary jaw face as their DX-Series counterparts, along with internal improvements over older DX models including a redesigned nut, new brush seal design and a new bearing pack.

The entire DX Manual, DXA Pneumatic and DXH Hydraulic vise lineup features the proprietary Kurt AngLock® spherical segment to create all-directional alignment, reduce jaw lift and improve performance. Featuring a convenient lift grip slot machined into the back of the fixed jaw, DX-style vises are easy to move around, load and position on a CNC machine table. All DX Crossover vises use sine keys for easy, accurate mounting and feature Kurt’s Lifetime Ironclad Warranty.

Kurt offers a lineup of electric and air-over-oil pumps to actuate DXH Hydraulic vises. Pumps and vises can be configured in a semi-automated workspace where an operator controls actuation with a hand lever, foot switch or toggle. A fully automated setup can be configured for actuation using a machine tool controller, PLC or a robot with the addition of solenoids, switches and a manifold. Kurt pumps can be set up to be single acting to close with hydraulic pressure and open via spring or double acting to open and close with hydraulic pressure. Double-acting setups are recommended for fully automated work envelopes. A single pump system can work with one vise or a multi-vise configuration.

About Kurt Workholding

Kurt Workholding has set the standard for quality and reliability with machine vises and workholding technology for over 60 years. Designed, manufactured and assembled in the USA, Kurt manufactures and sells a complete line of workholding products for the machining industry. The innovative angle-lock design vises have built our reputation and allowed expansion into a variety of other manufacturing sectors including 5-axis vises, workholding towers, automation and quality control. Kurt Workholding also provides manufacturers custom engineered solutions to help them maximize efficiency and quality.

100% employee-owned Kurt Workholding is a division of Kurt Manufacturing based near Minneapolis, MN. Operating in a state-of-the-art facility with multiple workstations, production lines and integrated automation with in-house design, engineering, production, assembly and shipping. Kurt employees own the manufacturing process from start to finish.