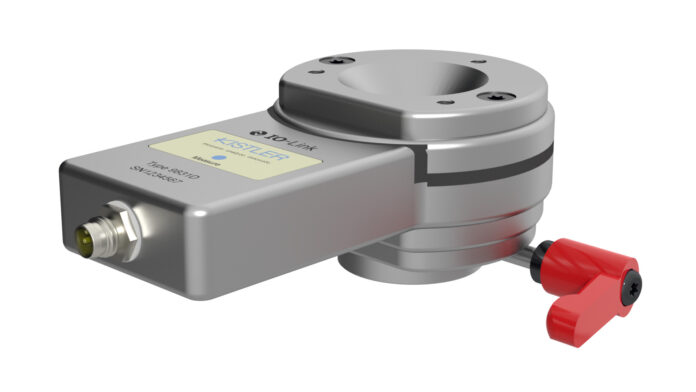

As well as analog output of the electrode force for resistance spot welding, the new Type 9831D welding force calibration transmitter from Kistler offers readout and configuration via the digital IO-Link interface as an option. IO-Link improves flexibility and interoperability to deliver a more user-friendly experience when testing and calibrating robotic welding guns, as well as the force and strain sensor technology integrated in them.

Resistance spot welding is a fastening method for metal sheets, plates and parts that is frequently used throughout industry – especially in the automotive, electronics and electrical sectors. To achieve optimum results, various welding parameters must be known and adjusted precisely to the welding process in each case. An appropriate welding force sensor makes it possible to measure the electrode force and allows in-situ calibration of sensors that are integrated in the structure.

Accurate and flexible measurement of welding forces

The new Type 9831D welding force calibration transmitter with IO-Link is the successor model to Kistler’s Type 9831C, which has become widely established in the market. The new welding force calibration transmitter is precalibrated and ready to operate immediately with a standard ex-works sensitivity of 1 mV/N. Advantages such as maximum measurement accuracy and repeatability ensure that this transmitter delivers reliable and trustworthy measurement results in every operational application. The Type 9831D is also equipped with integrated detection of the welding voltage – so users can record the welding duration in the resistance spot welding process and optimize it as necessary. Interchangeable inserts allow flexible use of this transmitter for various electrode types and diameters compliant with ISO 5821.

Digital data transmission with IO-Link

Analog measurement signals can be negatively affected by external influences as well as variations in cable lengths and their electrical resistances. With the help of IO-Link (the standardized communication system for connecting intelligent sensors and actuators compliant with IEC 61131-9), the welding force transmitter can send digital measurement data and receive input signals in real time – leading to a further improvement in measurement quality. Alongside these benefits, IO-Link enables remote configuration and monitoring of the device, so users can perform remote diagnoses and adjust settings more easily. Optional high- and low-pass filters as well as possibilities for signal inversion and amplification are just some of the additional features offered by the Type 9831D. As a standardized communication protocol, IO-Link also improves compatibility and interoperability among devices from different manufacturers. With these advantages, the new Type 9831D gives customers enhanced control, flexibility and integration capability for all specialized resistance spot welding systems and plants.

Developed for daily operation

Various mount adapters are available for the welding force transmitter, and the Quick-Mount adapter allows operation of the device by one person only. The device’s ground-insulated design improves workplace safety by preventing unintentional welding. An optional handle (already familiar from the Type 9831C predecessor model) is available to make it easier to transport the transmitter.

Closing words from Davorin Nägeli, Product Manager at Kistler: “Compared to its predecessor – which already has a long track record of success – the new welding force calibration transmitter offers various additional functions and a range of ingenious accessories that make it more efficient to operate. Thanks to the optional IO-Link interface, this measuring instrument can be integrated seamlessly into modern production environments: it’s all ready for Industry 4.0 – but there’s no loss of backwards compatibility with analog systems. Another plus: compatibility with welding controls from global market leaders make it easier to perform maintenance and calibrations in situ.”

About the Kistler Group

Kistler is the global market leader for dynamic pressure, force, torque and acceleration measurement technology. Cutting-edge technologies provide the basis for Kistler’s modular solutions. Customers in industry and scientific research benefit from Kistler’s experience as a development partner, enabling them to optimize their products and processes so as to secure sustainable competitive edge. Unique sensor technology from this owner-managed Swiss corporation helps to shape future innovations not only in automotive development and industrial automation but also in many newly emerging sectors. Drawing on our extensive application expertise, and always with an absolute commitment to quality, Kistler plays a key part in the ongoing development of the latest megatrends. The focus is on issues such as electrified drive technology, autonomous driving, emission reduction and Industry 4.0. Some 2,000 employees at more than 60 facilities across the globe are dedicated to the development of new solutions, and they offer application-specific services at the local level. Ever since it was founded in 1959, the Kistler Group has grown hand-in-hand with its customers and in 2022, it posted sales of CHF 434 million. About 8% of this figure is reinvested in research and technology – with the aim of delivering better results for every customer.