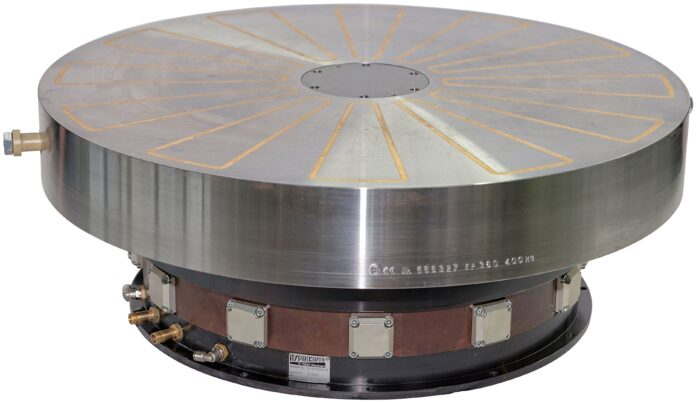

“Hyprostatik” rotary table systems are available with torque motor drive with angle measure system for C-axis or B-axis use or for belt drive for rotation use. Rotary tables available for measure machines with very high precision angle measure system up to 1,6m and 40to load.

With the use of the PM controller, several times stiffness is achieved compared to solutions using capillaries. This produces extraordinarily high stiffness with respect to radial, axial and moment loads. With the help of extensive computer programmes, an optimum in dimensioning is achieved regarding dynamic loads, so the best-possible damping is achieved. By precisely determining the limits of use and loads, an optimum in functional reliability is achieved.

Features of the rotary tables

Here is a list of features of the rotary tables:

– Radial and axial runout measured < 1.0 µm

– no wear, optimum damping,

– extremely stiff to radial, axial and moment load,

– high radial, axial and tilt torque load capacity,

– low thermal growth due to oil re-cooling, even at the highest rpm,

– very high rotational speeds possible,

– a wide range of sizes, designs, rpm and load capacities to meet customer needs,

– useful for horizontal, vertical or tilting orientation of rotation axis,

– with specially adapted hydraulic unit

About Hyprostatik Schönfeld

On 28.07.2022, hydrostatic systems specialist Hyprostatik Schönfeld GmbH (Germany) was acquired by the Schunk Group, thereby making it part of an international technology company. This step will further deepen the long-standing development partnership between Hyprostatik Schönfeld and OptoTech Optikmaschinen GmbH, which also belongs to the Schunk Group. The sale of Hyprostatik’s products will continue to take place directly via Hyprostatik Schönfeld. “We are pleased to be able to drive forward the development and sale of our hydrostatic products together with OptoTech. By joining the Schunk Group, a financially powerful, global technology group with a long-term strategy, we look forward to being able to guarantee our customers a reliable partnership in the future as well”, explains company founder Robert Schönfeld. “Hyprostatik and OptoTech are already linked by an intensive development partnership which is now being expanded and which will secure OptoTech a technological lead over the competition”, confirms Peter R. Manolopoulos, member of the Schunk Group Executive Board with responsibility for the Machinery & Equipment Division.

Hydrostatic components such as guides, lead screws and spindle bearings are predominantly used in high-precision machine tools, lathes and optical machinery. In OptoTech’s fine optics machines, the hydrostatic components ensure maximum precision in mechanical processing. Hydrostatic components from Hyprostatik Schönfeld are precise, virtually non-wearing, low-maintenance and energy-efficient.