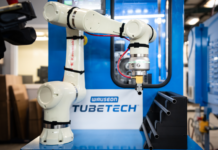

Flexxbotics announced the official launch of FlexxTend™, a turnkey automated machine tending solution for machine shops to automate their CNC machines.

Setting up a machine tending application takes time and effort. Especially when machine shops are busy trying to get parts out of the door. FlexxTend™ takes care of the whole process for you. Our team designs everything to your specification and can be onsite integrating, validating and training 6 weeks later.

FlexxTend™ helps to..

✓ Ensure rapid design and integration so your cobots go into production quickly, increasing your machine utilization and accelerating time to ROI.

✓ Eliminate the headaches and inefficient time figuring out an optimal setup. Let our expert team handle everything, so you can focus on production.

✓ Maximize functionality out of your machine tending setup by leveraging all the automation features of your CNC, cobot, and online services to enable lights out manufacturing.

✓ Ensure robust operations and support by providing the tools to be able to run high mix low volume jobs.

Tyler Bouchard, Co-founder & CEO at Flexxbotics, said: “One of the key benefits of FlexxTend™ is that it gives us direct access to the systems so we can recognize downtime, troubleshoot issues, and provide direct changes to programs, all remotely. It’s like all of our customers have a Flexxbotics Automation engineer onsite all the time.”

Tyler continues: “We’re incredibly excited to launch the FlexxTend™platform which optimizes the design of your work cell so you can handle multiple parts, conduct rapid changeover, and run lights out manufacturing.”