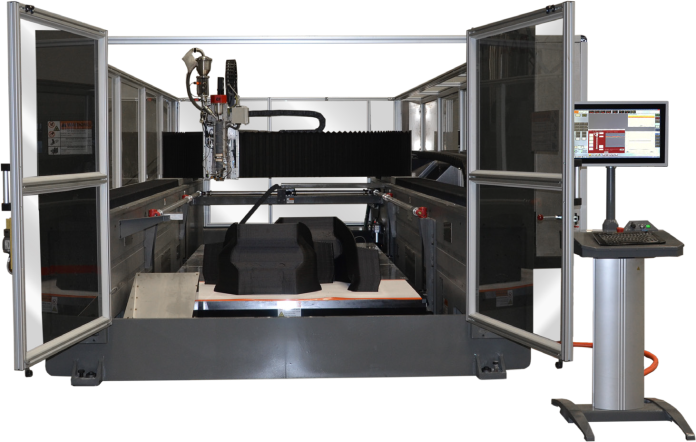

Cincinnati Incorporated (CI), a U.S.-based, build-to-order machine tool manufacturer, will introduce a 3D printed light resin transfer molding (LRTM) tool that was printed on its Big Area Additive Manufacturing (BAAM) machine. The mold consists of an upper and lower piece, and it will help determine the efficacy of replacing existing methods with additive manufacturing.

CI will exhibit in booth I-615, as will Design Concepts Marine Concepts (DCMC) in booth 3-1031 at the IBEX boat-building trade show in Tampa, Florida. DCMC is a cutting edge composites manufacturer with a skilled 3D CAD and engineering staff that designs, engineers, machines, 3D digitizes, tests and evaluates CNC plugs, composite molds, CNC parts, composite parts, limited production, scale models and CNC cold mold kits.

“The printed mold display at IBEX will be a prototype of what we envision this ultimately becoming,” said Alex Riestenberg, Additive Manufacturing Project Manager at CI. “One of the benefits of 3D printing is how quickly a process can evolve and be perfected, and this mold will showcase what the BAAM is capable of.”

“We pursued 3D printed LTRM patterns to explore the cost savings in the method as well as durability during the molding process,” said Ross Kennedy, Director of Business Development at DCMC. Although this method is not yet ready for production, we do see the potential of the application and plan to continue development with CI.”

“We pursued 3D printed LTRM patterns to explore the cost savings in the method as well as durability during the molding process,” said Ross Kennedy, Director of Business Development at DCMC. Although this method is not yet ready for production, we do see the potential of the application and plan to continue development with CI.”

CI first exhibited at IBEX in 2015, when it tested the waters to gauge the interest level in additive manufacturing. In the years since, the company has made big leaps forward and has developed applications across many industries. Mold making for the boat industry has a lot of potential, and the topic will be a focus in booth I-615 during IBEX 2019.

CI’s BAAM machine made its public debut at IMTS 2014 with partners Oak Ridge National Labs and Local Motors, and the world’s first 3D printed car drove off the showroom floor. Since then, rapid prototyping and press brake tooling applications have proven to be a great fit for additive manufacturing technology, and both will be on display at IBEX. The 3D printed mold display at the show will be roughly six feet wide, three feet deep and four feet tall. The two mold halves were printed in just 6 hours, and are made out of carbon fiber reinforced ABS plastic.

About Cincinnati Incorporated

Cincinnati Incorporated is one of a handful of U.S.-based, build-to-order machine tool manufacturers, and has shipped more than 50,000 machines in over 100 years of operation. From a modern 500,000-square-foot plant and technical center on an 80-acre campus near Cincinnati, Ohio, the company engineers and builds machines to the standard of ruggedness required in the North American market – with premium engineering features that stand up to years of rigorous use in demanding environments.

About Design Concepts Marine Concepts

DCMC, founded in 1976, has over 300,000 sqft of space between its Cape Coral and Sarasota, Florida locations. The company has long been a leader in the composite industry, relying on advanced technology and technical prowess to produce composite molds, CNC molds, CNC parts, composite parts, and even limited production, scale models and CNC cold mold kits.

About IBEX

IBEX is North America’s largest technical trade event in North America for marine industry professionals and is powered globally by METSTRADE, the world’s leading platform and community for professionals in the leisure marine equipment industry.