CNC system MTX: Consistently higher performance through higher computing power, realtime automation bus Sercos and fast I/O system.

Thanks to increased computing power in the control hardware, the CNC system MTX from Bosch Rexroth achieves even shorter cycle times and better machining quality. With the new XM42 embedded controller, systems with an extremely large number of axes and stations can now be efficiently automated with just one central controller. This simplifies project planning and reduces costs and complexity. With the elimination of communication in multi-control solutions, performance increases even further. The CNC system MTX uses open standards and protocols throughout and, with its Open Core Interface, offers machine manufacturers the opportunity to implement their know-how independently and securely.

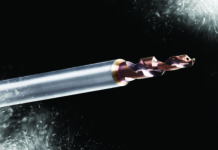

With an interpolation cycle of 250 μs, the MTX from Rexroth sets standards for CNC machining. The cores of the multi-core processor, assigned to the respective tasks, process the CNC, PLC and communication tasks independently of each other. Even under the full load of one task, the computing capacities of the other cores are available without restriction for high-speed processing without any negative interaction.

Due to the high computing power of the XM42 controller, machine manufacturers can, for example, control a large number of axes in rotary transfer machines with only one control hardware or significantly reduce cycle times in standard applications such as free-form surface machining. Real-time communication between drives and controller is handled by the Sercos automation bus. The fast S20 I/O system from Rexroth shortens response times and additionally increases control quality for process data.

The open CNC system solution allows machine manufacturers to extend the functionalities of the controller independently with high-level language programming using Open Core Interface technology. A number of manufacturers utilize this to protect their process know-how for laser, plasma and waterjet cutting. With the integrated OPC UA server, the CNC solution MTX also fits into future-proof network environments and exchanges information with other machines and higher-level systems.

Bosch Rexroth offers finely scaled MTX variants for CNC machining in terms of performance and function, from a compact solution for standard machines to the powerful versions for complex and very fast machines. All versions and generations are based on the same software core and use Rexroth IndraWorks as a central project planning and commissioning tool. This enables manufacturers to automate entire families of machine tools to suit their applications with minimal engineering effort.

About Bosch Rexroth

As one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth ensures efficient, powerful and safe movement in machines and systems of any size. The company bundles global application experience in the market segments of Mobile Applications, Machinery Applications and Engineering, and Factory Automation. With its intelligent components, customized system solutions and services, Bosch Rexroth is creating the necessary environment for fully connected applications. Bosch Rexroth offers its customers hydraulics, electric drives and controls, gear technology, and linear motion and assembly technology, including software and interfaces to the Internet of Things. With locations in over 80 countries, more than 30,500 associates generated sales revenue of approximately 5.5 billion euros ($6.2 billion) in 2017.

About Bosch

Having established a regional presence in 1906 in North America, the Bosch Group employs nearly 34,500 associates in more than 100 locations, as of December 31, 2017. In 2017 Bosch generated consolidated sales of $13.7 billion in the U.S., Canada and Mexico.

About the Bosch Group

The Bosch Group is a leading global supplier of technology and services. It employs roughly 402,000 associates worldwide (as of December 31, 2017). The company generated sales of 78.1 billion euros ($88.2 billion) in 2017. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT company, Bosch offers innovative solutions for smart homes, smart cities, connected mobility, and connected manufacturing. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to deliver innovations for a connected life. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 440 subsidiary and regional companies in 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. The basis for the company’s future growth is its innovative strength. At 125 locations across the globe, Bosch employs some 64,500 associates in research and development.