TRUMPF has introduced Remote Operations Support, a new service for automated laser cutting machine customers in the United States. The service connects experts in Germany with U.S.-based customers operating TruLaser Center machinery.

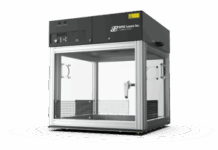

Designed for autonomous production, TRUMPF’s TruLaser Center is a full-service laser machine that automates the entire laser cutting process from loading of sheet metal to laser cutting and then part removal and sorting. The Remote Operations Support service was created to assist customers with this automated laser cutting technology.

“Many fabricators run the TruLaser Center during night shifts with the goal of arriving in the morning to a stack of finished and sorted laser-cut parts,” explains TruServices Director Christine Benz. “But what if a machine stops while no one is onsite? Or, what happens if an operator is out sick or on vacation? This is where the Remote Operations Support can intervene and help if needed.”

Better Night Shift Productivity

Small errors can cause big problems for fabricators, particularly when machines run unattended, and can result in lost production time. TRUMPF’s Remote Operation Support service increases nighttime production capability and reduces the need for additional onsite staff.

“It can be hard for manufacturers to find enough qualified employees to monitor the night shift, and delays in detecting and restarting a stopped machine could reduce overall efficiency,” adds Benz. “Fortunately, we have TRUMPF experts who are wide-awake at that time and available to provide remote service support.”

Remote Support for Increased Uptime

With Remote Operations Support, a team of TRUMPF experts in Neukirch, Germany remotely monitors TruLaser Center machinery in the United States. In addition to observing the process, the team can intervene and resolve errors to keep the laser cutting machine producing parts.

“This is another example of how TruServices is working to maximize our customers’ machine uptime,” says Benz. “If the machine encounters an error during an unattended night shift, our Remote Operations Support team can quickly resolve many unplanned machine stoppages and maintain the high level of productivity that is possible with the TruLaser Center.”

Future Oriented Service

The average processing time to remotely resolve a TruLaser Center machine standstill is estimated at less than fifteen minutes. In addition, the experts at TRUMPF have found that more than fifty percent of machine downtimes can be resolved remotely.

“We are continually enhancing our TruServices offerings to further the goal of zero unplanned downtime for customers,” says Benz. “Remote Operations Support is just one of the many ways TRUMPF is working to further increase manufacturing productivity and excellence in the future.”

About TRUMPF

TRUMPF is a high-tech company offering manufacturing solutions in the fields of machine tools and laser technology. It drives digital connectivity in manufacturing through consulting, platform products, and software. TRUMPF is one of the technology and market leaders in highly versatile machine tools for sheet metal processing, and in the field of industrial lasers. In 2023/24, TRUMPF employed approximately 18,550 people and generated sales of around 5.2 billion euros (preliminary figures). With about 90 companies, the TRUMPF Group is represented in Europe, North America, South America and Asia. The company has production facilities in Germany, France, the United Kingdom, Italy, Austria, Switzerland, Poland, China, the Czech Republic, the United States and Mexico.