Attendees at the International Manufacturing Technology Show (IMTS) 2022 will experience the most powerful machining software from CNC Software, LLC to date, Mastercam 2023. IMTS is the largest and longest-running industry trade show in the Western Hemisphere, held every other year in Chicago, attracting an international audience of more than 115,000 people. This year, visitors can investigate the latest functionality of Mastercam at booth # 133222 and at the Student Summit booth #215200 at McCormick Place, Chicago, IL, September 12-17.

Stas Mylek, Partnerships Program Manager at Mastercam, will be presenting Digitalization of the Manufacturing Floor: Are SMEs Ready for the Next Wave? on Monday, September 12, from 3:15 – 4:10 P.M. in room W192-C. He will cover how emerging digitalization will impact small and medium machine shops, and how best to prepare for change. The company will be on display throughout the IMTS show floor, with over 40 parts being programmed in partner booths such as MC Machinery (338129), Okuma (338500), Doosan (338900), and FANUC (338919). Meanwhile, in the company’s booth, Mastercam partners, Resellers, and employees will be giving presentations every hour Monday – Friday on many different topics and features.

Manufacturers from all over the world got the chance to test-drive Mastercam 2023 during the Public Beta Program before it was released and provided valuable feedback to help shape the final 2023 product. Many of the improvements in Mastercam 2023 are directly driven by the company’s users and shops. Feedback from Public Beta releases, shop visits, customer surveys, and consultation with our expert industry partners create the practical, shop-driven focus that helps ensure users’ success.

Consolidating Multiaxis Toolpaths

Morph, Parallel, Along Curve, and Project Curve are no longer individual toolpaths in Mastercam 2023. Instead, the Unified toolpath allows access to these cut patterns when you add the appropriate curves. For example, to create a toolpath that morphs between two surfaces, select Unified from the Multiaxis toolpaths, and then set the Cut Pattern to two surfaces with the Morph style.

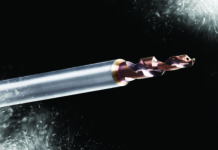

Detecting Undercut Stock When Machining

The Dynamic OptiRough and Area Roughing toolpaths can now be aware of undercut stock conditions, resulting in improvement to the toolpath motion, including less air cutting.

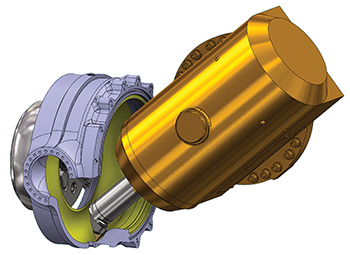

New B-Axis Contour Turning Toolpath

Mastercam 2023 introduces a new toolpath to the Turning suite for the Mill-Turn product. B-Axis Contour Turning is a finishing toolpath that allows for rotation of the B-axis while the tool is cutting. The toolpath features a top-down workflow and provides you with either Automatic or Manual motion control. Automatic mode produces safe toolpath motion that keeps the insert in contact with the contour. Manual mode offers full control over the B-axis angles along the contour.

About Mastercam

Mastercam, the world’s most widely used PC-based CAM package provides solutions for 2 axis, 3 axis, simultaneous 4 axis & 5 axis milling, multi axis lathe, live tooling, Wire EDM and routers.