Koyo Machinery USA, a leading provider of precision grinding machines and systems for production applications, has integrated into JTEKT Machinery’s range of products, services, and customer support operations.

This merger is an extension of JTEKT Corporation’s global brand unification initiative launched in 2021 which is designed to strategically reshape the company for increased efficiency and greater synergy between group companies, said Michael Defer, President and CEO, JTEKT Machinery Americas Corporation. “This is a positive change that will provide higher value and benefits to our customers,” according to the company.

With the JTEKT affiliation dating back to 2006, this development now formally integrates KOYO into JTEKT Machinery’s operational infrastructure which means the capacity for customer service and support is significantly expanded.

Expanded capabilities include service responsiveness, a larger spare parts and support organization, strengthened engineering resources, and a vastly improved machine and component rebuild division.

Koyo remains in Michigan

Additionally, Koyo Machinery’s operational core will remain in the Detroit area, moving to JTEKT Machinery’s Wixom, Michigan facility. All existing Koyo Machinery customers are encouraged to direct service and parts inquiries to JTEKT Machinery’s primary support lines, while the existing contact Koyo information will remain active for the foreseeable future. Koyo had been headquartered in Plymouth, MI.

Leading grinding machine manufacturers around the world have relied on technology for high volume precision grinding. Each machine is designed and built to provide reliable long-term performance.

Koyo machines include centerless, surface and special purpose grinders, such as silicon disc grinders. The company recently demonstrated a new double-disc horizontal grinder that simultaneously grinds both sides of silicon wafers to +/- 1 micron from as-sliced condition. The DXSG320 performance represents a massive improvement in accuracy and productivity over the single-spindle vertical grinders common in the chip industry today which grind to 3-4 microns, according to the company. The new machine design is a first in the industry.

A single, trusted source

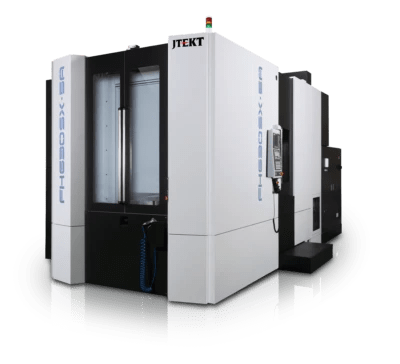

“Our primary lines—Koyo grinders and JTEKT machining centers and grinders–combine with our additional turning and large bridge machines, to create synergistic strengths for supporting manufacturing in diverse industries with metalcutting machines including horizontal and vertical machining centers, bridge mills, boring mills, and grinding machines,” said Mr. Defer. “We can add to that our automation, application engineering, controls and rebuild services to provide our customers end-to-end lifetime support of their manufacturing from a single, trusted source.”

About JTEKT

For more than 40 years, the company has provided an extensive line of CNC machines engineered for innovators and built with the speed, strength and capacity to get the job done. Its extensive lineup includes horizontal and vertical machining centers, bridge-type mills, turning centers, grinding machines and automation solutions. From job shop applications to high-volume production, thoughtful application engineering has been the cornerstone of the company’s machine tools. Built to be ruggedly tough in high-production environments, JTEKT machines provide the efficiency and precision required to deliver the products of tomorrow.