The Urus super SUV from Lamborghini is manufactured under the most modern conditions. The plant at the headquarters of the Italian sports car manufacturer in Sant’Agata Bolognese, which was rebuilt in record time, features a highly flexible assembly lines with newly developed AGVs (Automated Guided Vehicles) and ergonomic workstations. As the general contractor, Dürr was responsible for the installation of the assembly lines as well as for the integration and optimization of innovative technologies and processes.

With a view to the market launch of the new Urus super SUV, Lamborghini modernized its long-established plant within 18 months during ongoing production. Not only was the production space doubled from 80,000 m2 to 160,000 m2, but also the overall capacity expanded to 7,000 vehicles annually. For this strategically important project for the future of the brand, Lamborghini entrusted Dürr with developing new production lines for complete vehicle assembly. This is based on a forward-looking layout in which each area can be used flexibly. That allows the line configuration to be modified at any time and adapt to changing requirements.

AGV fleet in various sizes

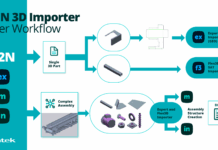

The conveying system with AGVs, specifically developed by Dürr for the Urus, guarantees a high degree of flexibility. The AGVs move individual components and bodies separately instead of one after another in a linear conveyor system as had been the case. They run without rails and are freely programmable like robots. This means that future model series can be manufactured on existing lines, since they can be changed over quickly to accommodate new market scenarios and varied production requirements. The AGVs at Lamborghini come in three different sizes and are suitable for line feeding tasks, the processes in the main line, and for subassembly and powertrain operations.

Ergonomically optimized workstations

In addition to the AGVs, Dürr installed other technologies that meet the demanding standards for ergonomics in the workplace. These include loading carriers (body on AGV), unloading devices (car from AGV), rotating and vertical adjustable carriers for body transport and lifting, as well as slat conveyors with a lifting table for moving the vehicle into an ergonomic position.

Overall control of the project on behalf of the Dürr Group rested with CPM, its Italian subsidiary specializing in final assembly. CPM and Lamborghini were already working together on layout design for conveyor technology, assembly lines, marriage stations, trim lines, and the end-of-line area. CPM was supported by its German colleagues from Dürr Assembly Products which supplied the x-road roll/brake test stand and adjusted it precisely to meet requirements for production of the Urus model.

Flexible line configuration for Urus assembly thanks to innovative solutions from Dürr.

About the Dürr Group

The Dürr Group has been established in the United States since 1970 and currently employs around 880 people. From the new Campus with a state-of-art validation, testing, and training center in Southfield, MI, Dürr USA represents four of the five divisions. Paint and Final Assembly Systems offers equipment for painting and assembly processes, while Application Technology provides paint application systems. Dürr’s Clean Technology Systems is the global leader in air pollution abatement and energy efficient technologies. The subsidiary Schenck Trebel Corporation, based in Deer Park, New York, offers balancing machines, vibration and condition monitoring systems and services for the general industry. The customers of Dürr USA include automotive and commercial vehicle manufacturers as well as their suppliers, and a diverse group of other industries. HOMAG Machinery North America operates the production facilities for HOMAG Group in Grand Rapids, MI, which is also the base for sales and service company Stiles Machinery Inc.

The Dürr Group is one of the world’s leading mechanical and plant engineering firms with extensive expertise in automation and digitization/Industry 4.0. Products, systems and services offered by the Group enable highly efficient manufacturing processes in different industries. Dürr supplies sectors like the automotive industry, mechanical engineering, chemical, pharmaceutical and woodworking industries. The company has 92 business locations in 31 countries. The Group generated sales of € 3.71 billion in 2017. In October 2018 Dürr acquired the industrial environmental technology business of US company Babcock & Wilcox, comprising the MEGTEC and Universal brands. Since then, the company has had over 16,000 employees and 108 business locations in 32 countries. The Group operates in the market with five divisions:

· Paint and Final Assembly Systems: paint shops and final assembly systems for the automotive industry

· Application Technology: robot technologies for the automated application of paint, sealants and adhesives

· Clean Technology Systems: exhaust-air purification systems, noise filtration systems and energy efficiency technology

· Measuring and Process Systems: balancing equipment as well as assembly, testing and filling technology

· Woodworking Machinery and Systems: machinery and equipment for the woodworking industry