Over the past six months, every industry in the world has been impacted in some capacity by the COVID-19 pandemic. Standard operating procedures and 2020 projections were quickly scrapped as companies realized they were operating on a new playing field that has never been traversed or even imagined. Through all the hardship and adaptation businesses faced, there was one clear lesson to be learned; organizations must accelerate their utilization and investment in their digital transformation plans. Specifically, those in manufacturing realized the previously stable global supply chains and operations could actually be overpowered by the unknown. Meanwhile, many other businesses and medical organizations were caught off guard, a beacon of support made its way to the forefront: 3D printing.

Over the past six months, every industry in the world has been impacted in some capacity by the COVID-19 pandemic. Standard operating procedures and 2020 projections were quickly scrapped as companies realized they were operating on a new playing field that has never been traversed or even imagined. Through all the hardship and adaptation businesses faced, there was one clear lesson to be learned; organizations must accelerate their utilization and investment in their digital transformation plans. Specifically, those in manufacturing realized the previously stable global supply chains and operations could actually be overpowered by the unknown. Meanwhile, many other businesses and medical organizations were caught off guard, a beacon of support made its way to the forefront: 3D printing.

While the world watched as the 3D printing community rushed to the aid of hospitals across the country to help supply them with essential personal protective equipment, other businesses realized the versatility of additive manufacturing. Not only were hospitals able to become more self-sufficient as they shortened supply chains, but they also saw flexibility in production and ease of access. As a result they were able they were able to print millions of copies of personal protective equipment during the pandemic to fix the shortages that were running rampant in healthcare organizations across the country. Due to the pandemic, Forbes predicts that over the next 18 months, manufacturing will experience five years’ worth of innovation. 3D printing technology is a key component of this trend, and as we move forward, companies will need to consider both hardware and software solutions as well as education of the technology to deliver tangible results in a shorter time than what they currently experience.

Knowledge Gap Remains a Key Barrier to Entry

Although this technology is primed and ready to be widely adopted across a wide variety of industries, its biggest obstacle is a lack of knowledge. According to the 3D Printing Sentiment Index, a survey of professionals across industries, two-thirds of US businesses that could potentially benefit from 3D printing do not use the technology at all, while only one in ten believe that they have progressed to a mature stage in their implementation of the technology. In fact, 69 percent of the professionals surveyed cited knowledge as the most frequent barrier to enter the market. Of those professionals, 40 percent also brought up a lack of necessary skillsets to properly leverage 3D printing. Lastly, just 16 percent of professionals said they would describe their level of knowledge regarding this technology as advanced or expert – demonstrating that the greater majority think their understanding is basic or rudimentary.

The Role of Software In Bridging the Gap

The Role of Software In Bridging the Gap

While those statistics might sound daunting, what they really demonstrate is a massive opportunity for growth. Businesses have already begun capitalizing on the opportunity but so many are still unsure of where to begin. The knowledge around 3D printing is attainable, but in general, most do not know where to go to seek information. Fortunately, companies in this sector are geared towards accelerating the world’s transition towards global digital manufacturing and making their resources accessible to those who would like to learn more. Software offerings for 3D printing provide an ecosystem that enables organizations to print the exact parts they need, when they need it, and where they need it, which allows them to capitalize on their return on investment.

Any company that is considering 3D printing should be well equipped with the necessary information and tools. With software, hardware, and materials working together effectively, users can ramp up quickly and streamline processes efficiently.

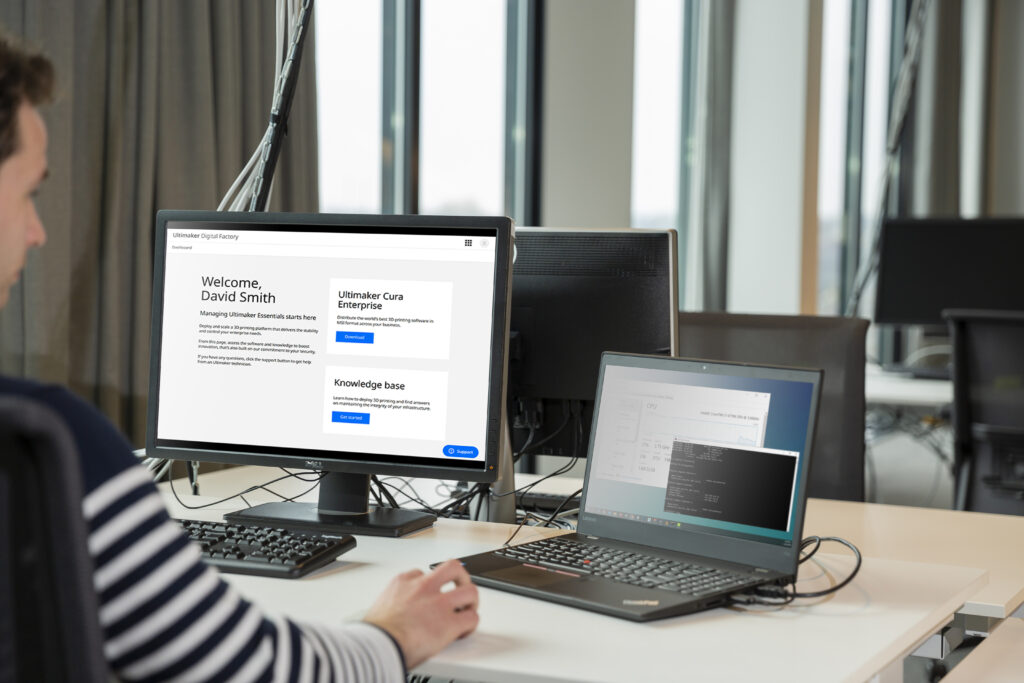

One of the key aspects of beginning a proper 3D printing operation is the software. For example, Ultimaker’s 3D printing software, Cura, can be utilized to prepare CAD for 3D printing. Cura is open-sourced, meaning that it is available to third-party users and individuals as well as those who already have an Ultimaker printer. Users can download free software like this to gain a better understanding of the technology behind 3D printing. Developed as easy to use software, both experienced and novice 3D printers can take advantage of the offerings to prepare 3D models for print within minutes. To help novice makers understand this technology better, the software has built-in tools and tips to assist with features that would usually require in-depth technical knowledge.

While the open-sourced software is able to put the technology in the hands of the end-users allowing them to test the capabilities of themselves and the ability of the 3D printing technology, there are still other educational opportunities that can help close the knowledge gap. To help businesses uncover how 3D printing can benefit their business now and in the future, Ultimaker launched the 3D Printing Academy. These eLearning modules are designed to bring any level employee up to speed for any sort of role or responsibility in the growing 3D printing market. With role-specific courses, users will be able to train and develop deep knowledge and skillsets that immediately impact their day to day efforts. Additionally, all of the courses have remote learning capabilities so those who enroll do not need to physically be on-site to receive their education.

Recently released Ultimaker Essentials, an enterprise IT solution to overcome barriers in additive manufacturing, comes with three additional eLearning courses. Those who adopt 3D printing often learn to produce only one item and do not realize the full capabilities of the technology. The Academy lessons were launched in an effort to educate people and foster their development in the 3D printing space to the point where they can become a certified maker and scale up the technology in their own organizations. Users can collaborate, iterate, and innovate faster than ever before so their organizations can overcome real-time challenges faced every day.

Recently released Ultimaker Essentials, an enterprise IT solution to overcome barriers in additive manufacturing, comes with three additional eLearning courses. Those who adopt 3D printing often learn to produce only one item and do not realize the full capabilities of the technology. The Academy lessons were launched in an effort to educate people and foster their development in the 3D printing space to the point where they can become a certified maker and scale up the technology in their own organizations. Users can collaborate, iterate, and innovate faster than ever before so their organizations can overcome real-time challenges faced every day.

If companies did not already realize that global supply chains and manufacturing workflows could easily be disrupted, the pandemic surely made them recognize this potential issue. The transition to digital distribution and local manufacturing is imminent and 3D printing companies are focused on increasing education across potential users. Removing the final barriers and gaps of knowledge will help companies unlock the full potential that 3D printing provides. With both software that provides millions with the opportunity to openly work on projects and eLearning courses to strengthen the knowledge of users, the time for greater 3D adoption is now.