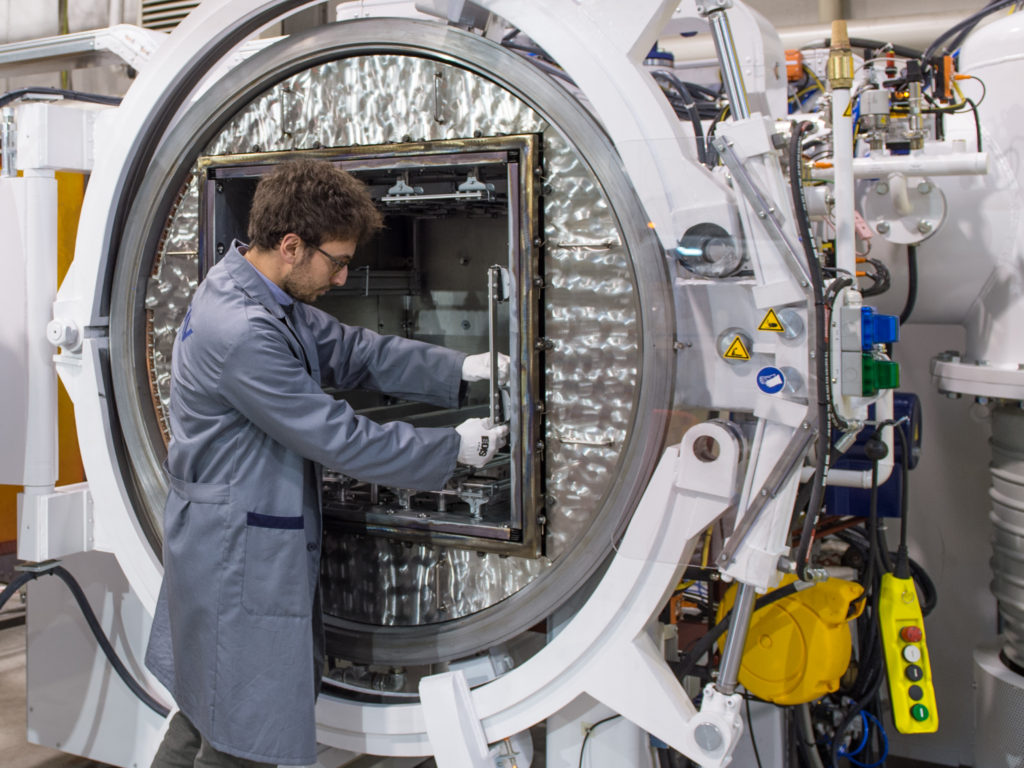

Heat treatment can be performed by different types of furnaces and ovens: these include vacuum systems. Parts processed in a vacuum have surfaces that are either carburized nor decarburized and consequently exhibit superior performance. Vacuum furnaces provide unreactive conditions for the materials being treated that ensure development of the optimum properties desired.

One of the key components of a vacuum furnace is the hot zone, as it contributes to the performance of the whole system. Choosing the proper hot zone for the materials and processes to be run is one of the most important initial decisions.

The Advantages of Vacuum Heat Treatment

Vacuum heat treating is used to prevent reactions at the surface of the material, such as oxidation; to remove surface contaminants such as oxides, traces of lubricants and other dissolved substances from metal; add a carburizing layer to the surface; join metals by brazing or diffusion bonding. Controlled thermal processing of components is carried out in a vacuum environment to eliminate the deleterious effects of the charge reacting with the gases present in air.

Moisture, oxygen, carbon dioxide and hydrogen are present in significant amounts in the atmosphere. Each of these aspects can react to varying degrees with many different metals. While many of these reactions occur to only a small extent at room temperature, they are often greatly accelerated in the presence of heat. In a vacuum, most of the air and its reactive elements are removed from the heat treating environment.

Moisture, oxygen, carbon dioxide and hydrogen are present in significant amounts in the atmosphere. Each of these aspects can react to varying degrees with many different metals. While many of these reactions occur to only a small extent at room temperature, they are often greatly accelerated in the presence of heat. In a vacuum, most of the air and its reactive elements are removed from the heat treating environment.

This leaves the surface of the material free from flaking or discoloration and therefore reduces the finishing time of the material after heat treatment. Most steels which can be vacuum treated have lower distortion levels than conventional oil hardened tool steels. Reduced distortion following treatment means a greater proportion of treated product will be suitable for use or for further processes.

Key Features and Components of Vacuum Systems

Uniformity of temperature is of great importance to heat treatment results. The most common complaints about heat-treating system concern non-uniform temperature. These problems are not restricted to low-cost systems but are common to almost all heat-heating systems.

In many heat processing applications temperature uniformity of the product at the end of cycle is sufficient criteria for producing an acceptable product. But there are many applications in heat processing where time at temperature is the criteria. Even though the product temperature may be uniform at the end of cycle, the product may not be acceptable because different sections of the product will have had different time at temperature histories.

Ramping rate, temperature accuracy, stability, and temperature uniformity are most important points when customer evaluates an excellent system for heat treatment. Vacuumfurnaces can provide rapid and highly consistent heating in a controlled atmosphere, making them ideal for numerous heavy duty industrial and laboratory applications.

Ramping rate, temperature accuracy, stability, and temperature uniformity are most important points when customer evaluates an excellent system for heat treatment. Vacuumfurnaces can provide rapid and highly consistent heating in a controlled atmosphere, making them ideal for numerous heavy duty industrial and laboratory applications.

The choice of equipment varies with application. The design of the furnaces generally depends on the size of the load, the pressure (vacuum level) and temperature to be attained, and the medium (oil or gas) to be used in cooling the load. There are many factors that should be considered when selecting a vacuum furnace.

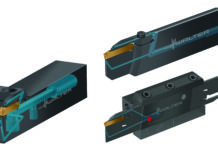

Although price is obviously important, there are many detailed design and other technical considerations buyers should evaluate to ensure that they select the right equipment for their requirements. The primary components of a vacuum furnace include hot zone, vacuum pumps, controls, and quenching system. The hot zone is by far the most critical component as it has an impact on the process quality, the temperature uniformity, the heating and cooling rates and the furnaces energy consumption.

Hot Zone: The Core of Every Vacuum Furnace

Vacuum is in itself a very good insulator. By providing small vacuum spaces between the parts of a furnace system, heat flow from the inside to the outside of the furnace can be greatly reduced. Because of this, most vacuum furnaces have essentially a heated, insulated chamber within a chamber, held away from the cold wall by supports. A layer of insulation material is supported off this inner chamber, and it in turn encloses the heating elements, workload, and work supports.

Vacuum furnace hot zones are manufactured using materials that can withstand temperatures of up to 2500°C (4532°F) or higher. Heating elements are generally made of graphite, molybdenum, or tungsten. Because the vacuum protects the heating elements from oxidation, the high-temperature properties of these materials can be fully utilized. Molybdenum and graphite are also the most popular choices for heat shields (insulation package) to protect equipment against the effects of radiant heat. On this matter, when the time comes to buy a new furnace, you will be asked to make some selections for structural components and heat shielding.

Comparison of Graphite And Molybdenum Heat Shields

Today, for the insulation of the hot zone most vacuum furnaces use graphite in the form of sheets, felt, and board in varying combinations and thicknesses. A standard graphite insulation package normally consists of a minimum thickness of 1.5 inches of graphite-based material in the form of layers of blanket or board. An inner face of graphite foil or foil-bonded carbon composite is added to enhance reflectivity.

These graphite-based materials have excellent insulating properties, are usually cheaper than metal heat shielding and are very easy to work with. The speed at which graphite lined hot zones reach their ultimate vacuum and their life depends strongly on the purity of the graphite. Not all the materials marketed are the same. Graphite is the heat treaters’ preferred option for most processes due to its longer life, lower replacement cost and reduced power consumption.

These graphite-based materials have excellent insulating properties, are usually cheaper than metal heat shielding and are very easy to work with. The speed at which graphite lined hot zones reach their ultimate vacuum and their life depends strongly on the purity of the graphite. Not all the materials marketed are the same. Graphite is the heat treaters’ preferred option for most processes due to its longer life, lower replacement cost and reduced power consumption.

A furnace with this type of heating chamber is the best solution at least for the more conventional vacuum treatments. On the downside, there are also less positive aspects regarding graphite’s capacity to adsorb vapors and the risk of graphite micro-particles being released.

Of the various types of refractory metals in use, none is more common than molybdenum (Mo). Its strength and stability at elevated temperatures make molybdenum an attractive material for use in the fabrication of conventional all-metal hot zones. It has a high meltingpoint, low vapor pressure and is extremely effective at reflecting heat. In fact, molybdenum is seven times more effective than steel at reflecting heat, so when you have one layer of molybdenum it has the same effect as seven layers of steel. All-metal hot zones are used in high demand industries, where high-vacuum or very clean processing environments are required, such as aerospace, electronics and medical.

Of the various types of refractory metals in use, none is more common than molybdenum (Mo). Its strength and stability at elevated temperatures make molybdenum an attractive material for use in the fabrication of conventional all-metal hot zones. It has a high meltingpoint, low vapor pressure and is extremely effective at reflecting heat. In fact, molybdenum is seven times more effective than steel at reflecting heat, so when you have one layer of molybdenum it has the same effect as seven layers of steel. All-metal hot zones are used in high demand industries, where high-vacuum or very clean processing environments are required, such as aerospace, electronics and medical.

However, care must be taken in operating furnaces with all-metal hot zones because molybdenum embrittles due to recrystallization after a single exposure to temperatures above about 1150°C (2100°F). Molybdenum tends to form oxides when oxygen is present (also at low temperatures) and such oxide has a greater emissive power. Material “colouration” due to the presence of traces of oxygen or material evaporating from the pieces alters and reduces the shielding conditions and also compromises the ability to achieve the thermal uniformity.

When it comes to hot zone, making the right choice for insulation will ensure the highest quality product. If your process cannot tollerate incidental dust or dirt, an all-metal hot zone is the right solution. This include medical applications requiring an ultra-clean environment and processes such as diffusion bonding and aluminum brazing. Graphite is also capable of producing bright and clean parts, but incidental carbon dust can also occur. If your material does not react with carbon, then you have the flexibility to choose between hot zones.

About TAV VACUUM FURNACES

TAV VACUUM FURNACES is a specialized manufacturer of industrial vacuum furnaces and ovens. Started in 1984, TAV VACUUM FURNACES has developed an accurate knowledge of all these technologies and their performance, also providing special solutions and bespoke systems to process innovative materials and sensitive products. Our customers are the major aeronautic and aerospace companies, the most advanced heat treatment shops, IGT manufacturers, heat exchanger manufacturers, sintering specialists and the most prestigious laboratories world-wide.