Bystronic offers its customers solutions that make them even more competitive: From stand-alone laser cutting systems or pressbrakes, through automation solutions, all the way to a complete Smart Factory, “World Class Manufacturing” for every sheet metal processing enterprise.

With the message “Grow with our smart solutions,” Bystronic has brought numerous introductions to the market last fall to help sheet metal processors remain competitive in an increasingly tough field. From manual production, through automated production, all the way to the Smart Factory, Bystronic solutions help companies look to the future with success, thanks to optimized processes.

With three main categories of solutions, tailor-made for the individual needs of each client, Bystronic offers “World Class Manufacturing” solutions for all customer requirements.

1. Manual Production: Greatest Flexibility

When flexibility is called for in cutting and bending, Bystronic solutions give customers the range to flexibly implement even small batch sizes.

Bystar Fiber 15 Kw – The Bystronic High-End Fiber Laser

Speed, precision, flexibility: With the new laser power of 15 kilowatts, the ByStar Fiber precisely cuts steel, aluminum, and stainless steel in the range of 1–30 millimeters, and brass and copper up to 20 millimeters. Laser power thus increases by up to 50 percent, and sheet metal processors further optimize their production.

Speed, precision, flexibility: With the new laser power of 15 kilowatts, the ByStar Fiber precisely cuts steel, aluminum, and stainless steel in the range of 1–30 millimeters, and brass and copper up to 20 millimeters. Laser power thus increases by up to 50 percent, and sheet metal processors further optimize their production.

More information: bystarfiber.bystronic.com

Bytube Star 130 – Tube Processing Made Easy

Sheet metal processors speed up their tube laser business with the new ByTube Star 130, the high-end tube laser with the most functions. Precision, user-friendliness, and a fully automatic setup with open profiles and ellipses lead to greater flexibility and quality in production.

More information: bytubestar.bystronic.com

Bybend Star 120 – Compact, Fast, And Powerful

Speed and power in the bending process: The most compact solution for fast bending of small and medium-sized parts in the widest variety of material thicknesses and qualities – with the highest precision.

Customer satisfaction and quality are top priorities for Bystronic. The Bystronic laser cutting and bending systems were developed to optimize customers’ production processes as efficiently as possible. As a result, with Bystronic high-performance fiber laser cutting machines and precision bending machines, customers have the perfect conditions in which to flexibly adapt their production to the changing demands of the market.

2. Automated Production: Efficiency Around the Clock

More and more sheet metal processors want to continue production through the night so they can be even more efficient and productive. Autonomous, automated, secure: Bystronic cutting and bending cells make this possible, thanks to mobile automation solutions, even within the smallest of spaces.

Mobile Bending Cell – Compact Bending Automation

Mobile automation for high-speed bending: Bystronic is expanding the Xpert series to include the Mobile Bending Cell. This provides a compact solution for quickly switching between manual and automated bending.

More information: mobilebendingcell.bystronic.com

ByTrans Modular – the flexible loading and unloading solution

ByTrans Modular – the flexible loading and unloading solution

Larger capacity thanks to leading technology and bundled automation expertise: The new loading and unloading system ByTrans Modular manages any order situation with intelligent material handling, optimizing the performance of the laser cutting system. A big advantage is the modularity of the system, which presents an ideal solution for practically any sheet metal processor.

Robot Manager – Simple Software for Efficient Automation

The wide-ranging and powerful programming software for automated bending. With Robot Manager, sheet metal processors control and simulate the robotics in Bystronic bending automations. Efficiency and productivity represent automated production for sheet metal processing with Bystronic machines. Solutions from Bystronic help businesses optimize their production and thus use resources more efficiently.

The wide-ranging and powerful programming software for automated bending. With Robot Manager, sheet metal processors control and simulate the robotics in Bystronic bending automations. Efficiency and productivity represent automated production for sheet metal processing with Bystronic machines. Solutions from Bystronic help businesses optimize their production and thus use resources more efficiently.

3. Smart Factory: Ready for the Future

For sheet metal processing companies, there is enormous potential in networked production. Conveniently, Bystronic is the specialist for a fully integrated data and material flow.

For sheet metal processing companies, there is enormous potential in networked production. Conveniently, Bystronic is the specialist for a fully integrated data and material flow.

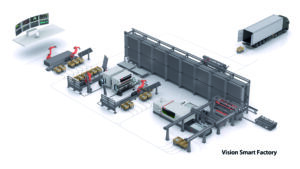

Smart Factory production – comprehensive networked production in action

For competitive production, fully automated production processes are necessary. They enable increased efficiency and productivity and ensure profitability.

Bysoft Suite – Intelligent Software For All Processes, From Tender To Delivery

The BySoft suite is the complete software ecosystem that turns the Smart Factory into a reality. Sheet metal processors accelerate their production and automate and orchestrate their business, enabling more agile decision-making that helps them adapt their enterprise to changed environments.

Smart Factory Solutions – Scalable Solutions for Smart Production

With scalable system solutions, Bystronic combines machines, automation, and software to create a flexible network of intelligent components. Thanks to the centralized control of networked components, the Bystronic software suite offers full transparency – at any time and from anywhere.

With scalable system solutions, Bystronic combines machines, automation, and software to create flexible networks of intelligent components for original equipment manufacturers (OEMs) and contract manufacturers. With centralized control, Bystronic offers full transparency – at any time and from anywhere. Sheet metal processing companies thus accelerate their production and workflows to stay one step ahead of their customers’ growing requirements.

About Bystronic

Bystronic is a globally leading technology company in the area of sheet metal processing. The focus is on the automation of the complete material and data flow of the cutting and bending process chain. The intelligent connectivity of laser cutting systems and pressbrakes with innovative automation, software, and service solutions is the key to comprehensive digitalization in the sheet metal industry.

Bystronic headquarters are located in Niederönz (Switzerland). Additional development and production locations are in Sulgen (Switzerland), Gotha (Germany), Cazzago San Martino and San Giuliano Milanese (Italy), Tianjin and Shenzhen (China), and Hoffman Estates (USA). We are actively represented by our own sales and service subsidiaries in more than 30 countries and by agents in numerous other countries. Bystronic AG is listed on the SIX Swiss Exchange (SIX: BYS).