Eliminating Handling

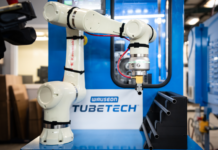

Collaborative robots take over manual handling of glass tubes in CNC glass lathe, increase capacity 50%

Family-owned Hofmann Glastechnik faced a challenge in hiring skilled workers for its glass manufacture and wanted to make better use of existing employees’ potential by freeing them from repetitive tasks. Looking into automation, the company chose two collaborative robot arms from Universal Robots (UR) to feed highly sensitive glass tubes into a CNC glass lathe. The UR robots stabilized the production process, improved quality, and increased capacity by 50 percent.

For more than five decades, the family business Hofmann Glastechnik GmbH has been producing technical glasses for laboratories, the medical field, and industrial appliances.  The company is one of the largest industrial glassblowing companies in the German market. With over 20 employees, Hofmann is an experienced specialist in the traditional craft of glassblowing and also a pioneer in the use of modern production technologies. The company produces glass items as both standard components and customer-specific tailor-made products for more than 350 regular customers and is an established supplier for companies such as Philipps and Siemens.

The company is one of the largest industrial glassblowing companies in the German market. With over 20 employees, Hofmann is an experienced specialist in the traditional craft of glassblowing and also a pioneer in the use of modern production technologies. The company produces glass items as both standard components and customer-specific tailor-made products for more than 350 regular customers and is an established supplier for companies such as Philipps and Siemens.