Flexxbotics, a pioneering force in industrial automation, stands at the forefront of revolutionizing the manufacturing landscape. With an unwavering commitment to innovation and excellence, Flexxbotics has positioned itself as a key player in the transition towards smart factory operations, where the synergy of advanced robotics and operational efficiency is redefining what’s possible in manufacturing.

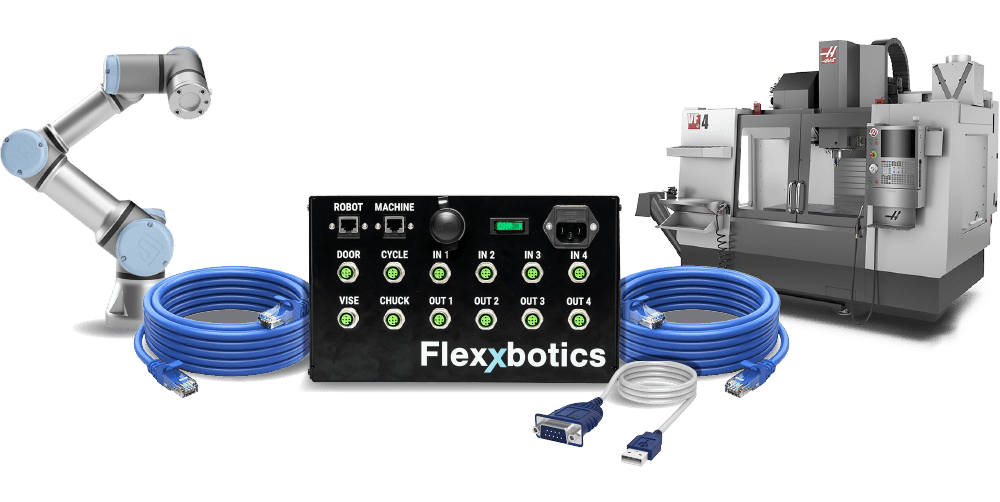

At the heart of Flexxbotics’ transformative solutions is its groundbreaking FlexxCORE technology. This patent-pending innovation represents a significant leap in robotic manufacturing, enabling secure and flexible connectivity between robots and CNC machines. FlexxCORE’s compatibility with an extensive range of machinery, including the sophisticated series of HURCO CNC machines, marks a new era in machine-robot communication. By integrating seamlessly with HURCO’s MAX®5 CNC control system, FlexxCORE technology enhances the operation of various machining centers, driving increased productivity, higher yields, and greater profitability.

Flexxbotics’ technological prowess extends beyond HURCO machinery, showcasing its versatility and commitment to addressing the dynamic needs of modern manufacturing. The collaboration with Makino machine tools is a testament to this, where Flexxbotics has successfully extended its reach to various machine tools, setting new standards in operational efficiency. The integration with Makino’s advanced Pro6™ CNC Control and Hyper-i™ control system, facilitated by FlexxCORE technology, empowers manufacturers to achieve higher throughput and increased profit margins.

Moreover, Flexxbotics has demonstrated its adaptability and technical excellence through its integration with Nakamura-Tome machinery, further broadening its impact across diverse manufacturing requirements. This integration ensures smooth operation and enhanced efficiency for various machine types, solidifying Flexxbotics’ role in the evolution of smart manufacturing solutions.

Flexxbotics’ solutions are not just limited to machine integration. The company’s unique SaaS/hybrid architecture ensures uninterrupted production with or without internet connectivity, compatible with a wide range of business systems like CAD/CAM, SCADA/HMI, IIoT, MES, ERP, and PLM. This architecture forms the backbone of the smart factory, enabling comprehensive control over connected machinery through advanced bidirectional communication capabilities.

As industries globally embrace the concept of the smart factory, Flexxbotics is leading the charge with its innovative solutions. Through its relentless pursuit of innovation and adaptability, Flexxbotics is not just keeping pace with the evolving manufacturing landscape but actively shaping the future of the industry. With a vision firmly rooted in enhancing efficiency, productivity, and sustainability, Flexxbotics is redefining industrial excellence and paving the way for a new era in manufacturing.

Revolutionizing HURCO® CNC Machines

Flexxbotics has achieved a significant technological breakthrough with its integration with HURCO CNC machines. This strategic partnership extends across a comprehensive range of machinery, from complex 5-axis machining centers to versatile turning centers. At the heart of this integration is Flexxbotics’ pioneering FlexxCORE technology, enabling secure, flexible, and efficient robot-machine communication. This technological synergy not only boosts productivity but also drives higher yields, propelling manufacturing units towards unprecedented profitability.

The FlexxCORE technology’s compatibility with HURCO’s MAX®5 CNC control system is a testament to its versatility, enhancing the operation of HURCO machines including the TM/X Series and VM/X Series. This integration represents a significant step forward in manufacturing, making environments more connected, streamlined, and productive.

Advancements with Makino Machine Technology

The collaboration with Makino machine tools further illustrates Flexxbotics’ commitment to technological versatility and innovation. Extending its advanced solutions to various Makino tools, Flexxbotics is broadening its impact across different manufacturing domains while setting new benchmarks in operational efficiency. The FlexxCORE technology underpinning this partnership enables robust robot connectivity, aligning with the dynamic demands of modern manufacturing.

Flexxbotics’ compatibility with Makino’s Pro6™ CNC Control and Hyper-i™ control system demonstrates a comprehensive approach to enhancing machine performance. This integration enables manufacturers to achieve higher yields, greater throughput, and increased profitability, crucial steps in realizing the full potential of modern manufacturing.

Integration with Nakamura-Tome Machine Tools

Flexxbotics’ adaptability and technological prowess are further showcased in its integration with Nakamura-Tome machinery. This compatibility highlights Flexxbotics’ ability to cater to diverse manufacturing needs, ensuring seamless operation and enhanced efficiency for various machine types. The inclusion of Nakamura-Tome’s machinery in Flexxbotics’ portfolio represents a comprehensive approach to smart manufacturing solutions, compatible with over 1000 different models of CNC machines.

SpiTrex Orthopedics Case Study: Achieving Remarkable Efficiency with Flexxbotics

The implementation of Flexxbotics solutions at SpiTrex Orthopedics exemplifies a transformative impact in manufacturing efficiency and productivity. SpiTrex faced significant challenges in enhancing productivity in their FOBA laser marking machine workcells. The integration of Flexxbotics’ advanced robotic solutions led to outstanding improvements, fundamentally altering their manufacturing process.

Results:

83% Reduction in Changeover Time

Previously, setting up a new job required over an hour of engineering time. With Flexxbotics’ solutions, this process has been streamlined remarkably, now taking less than 10 minutes. This drastic reduction in changeover time represents a leap in operational efficiency, enabling quicker transitions and minimizing downtime.

20% Reduction in Lead Time

The autonomous changeover process, combined with closed-loop feedback functionality, has been a game-changer for SpiTrex. This integration allows for the production of extremely high-tolerance parts through continuous flow, reducing overall lead time by 20%. This enhancement is crucial for maintaining competitiveness in the fast-paced manufacturing sector, particularly in the medical devices domain where precision is paramount.

10:1 Machine to Man Ratio

Implementing Flexxbotics across SpiTrex’s FOBA laser marking workcells achieved a 10:1 machine-to-man ratio. This significant improvement in operational leverage enables continuous operations, even amidst labor shortages. Consequently, SpiTrex has been able to ship more high-quality parts, addressing both efficiency and output quality.

Horizontal and Vertical Integration

The Flexxbotics solution provides comprehensive integration, both vertically from one FOBA machine to another and horizontally across prior workcells and IT systems. This integration exemplifies the seamless and interconnected nature of Flexxbotics’ solutions, enhancing the overall workflow and data coherence in SpiTrex’s manufacturing operations.

This case study demonstrates how Flexxbotics’ cutting-edge technology not only optimizes specific processes but also brings a holistic improvement to manufacturing operations, setting a new standard for efficiency and productivity in the industry.

Flexxbotics: Powering the Smart Factory Revolution and Showcasing Future Potential

Flexxbotics stands at the forefront of the smart factory revolution, fueled by its unique SaaS/hybrid architecture. This cutting-edge system is compatible with a broad spectrum of business systems, including CAD/CAM, SCADA/HMI, IIoT, MES, ERP, and PLM. It ensures uninterrupted production capabilities, regardless of internet connectivity, epitomizing the resilience and adaptability required in modern manufacturing environments. The advanced bidirectional communication features of Flexxbotics provide comprehensive control over connected machinery, establishing it as a cornerstone in the realm of contemporary manufacturing.

The impact of Flexxbotics extends beyond its core technology into the realm of industry exhibitions and showcases. The company is gearing up to demonstrate its technological prowess at the upcoming ATX West 2024. This event represents a significant opportunity for Flexxbotics to exhibit its capabilities and innovations to a wide array of advanced manufacturing companies and industry stakeholders. It’s an ideal platform to reinforce its position as a leader in industrial automation and smart manufacturing solutions.

In the arena of manufacturing efficiency, Flexxbotics’ influence is profound. The company’s solutions have been instrumental in reducing the need for manual intervention and significantly shortening setup times across various production processes. These advancements in yields, throughput, and profitability herald a new era in manufacturing productivity, marking a shift towards more efficient and streamlined operations.

Furthermore, Flexxbotics’ technology is meticulously designed to tackle the prevalent challenges in CNC automation. By enhancing the interaction between robots and machines, Flexxbotics ensures minimal downtime and maximizes efficiency gains. This strategic approach to problem-solving in automation establishes Flexxbotics as a visionary entity in the sector, adept at addressing and overcoming the complex challenges faced in modern manufacturing processes.

Preparing for the Future: Flexxbotics and Emerging Industry 4.0 Technologies

As we look to the future, Flexxbotics is not just poised to adapt to emerging Industry 4.0 technologies; it is positioned to be a catalyst for innovation and transformation in the manufacturing sector. The integration and evolution of Flexxbotics with upcoming technological advancements will further solidify its role as a leader in the smart manufacturing revolution.

Integration with Advanced Data Analytics and AI

Predictive Maintenance and Process Optimization: Flexxbotics is expected to integrate advanced data analytics and AI to enhance predictive maintenance capabilities. By analyzing data patterns, Flexxbotics could predict machine failures or maintenance needs, thereby reducing downtime and increasing productivity. AI algorithms can also be employed to optimize manufacturing processes in real-time, ensuring maximum efficiency.

IoT and Enhanced Connectivity

Real-Time Data Management: With the Internet of Things (IoT) becoming increasingly prevalent in manufacturing, Flexxbotics plans to enhance its connectivity features. The integration with IoT devices will allow for real-time data collection and management, providing a holistic view of the manufacturing process and enabling immediate adjustments to improve performance.

Augmented Reality (AR) and Virtual Reality (VR)

AR for Training and Maintenance: Flexxbotics is exploring the use of Augmented Reality (AR) for training purposes and remote maintenance assistance. AR can provide interactive, 3D visualizations of machinery and processes, making it easier for technicians to understand complex systems and perform maintenance tasks efficiently.

VR for Process Simulation: Virtual Reality (VR) integration could enable Flexxbotics to offer virtual simulations of manufacturing processes. This feature would allow manufacturers to test and refine processes in a virtual environment before actual implementation, reducing the risk of costly errors.

Collaborative Robotics and Human-Machine Interaction

Enhanced Collaboration with Cobots: Flexxbotics is likely to expand its portfolio to include more collaborative robots (cobots) designed to work alongside human workers. These cobots will be equipped with advanced safety features and intuitive interfaces, making them more accessible to the workforce and enhancing human-machine collaboration.

Sustainable Manufacturing Practices

Eco-Friendly Solutions: As sustainability becomes a priority, Flexxbotics is expected to focus on developing solutions that support eco-friendly manufacturing practices. This could include optimizing energy consumption, reducing waste, and implementing recycling processes within manufacturing operations.

Customization and Flexibility

Tailored Solutions for Diverse Industries: Acknowledging the diverse needs of different manufacturing sectors, Flexxbotics plans to offer more customized solutions. This approach will cater to the specific requirements of industries such as automotive, aerospace, and consumer electronics, providing flexibility and adaptability in manufacturing processes.

Paving the Way in Advanced Manufacturing

As we peer into the future of manufacturing, Flexxbotics stands distinct, not just as a participant in the Industry 4.0 landscape, but as a pioneering force charting new courses. This company is more than an entity adapting to change; it’s an innovator defining the very essence of modern manufacturing. Flexxbotics’ strategic embrace of cutting-edge technologies positions it to revolutionize standard manufacturing practices, steering the sector toward uncharted territories of efficiency and innovation.

Flexxbotics’ relentless commitment to innovation and adaptability uniquely equips it to significantly influence and sculpt the smart manufacturing landscape. By leveraging emerging technological frontiers, Flexxbotics is on a mission to elevate manufacturing processes to levels of efficiency and sustainability that were once thought unattainable. The company is tuned to the evolving needs of a diverse array of industries, ensuring its solutions are not only relevant but revolutionary. The journey ahead for Flexxbotics is more than a path of adaptation to new technologies; it represents a bold stride towards reimagining and reshaping the future of industrial operations.

Leading the Charge in Manufacturing Evolution

In an era marked by rapid technological evolution, Flexxbotics distinguishes itself as an influential leader in the manufacturing domain. The company’s innovative strategies and advanced solutions are actively directing the industry towards more streamlined, productive, and profitable practices. Flexxbotics is not just following the trends of smart factory development; it is at the forefront, molding these concepts into a tangible global reality.

Flexxbotics’ role in manufacturing automation goes beyond mere participation; it is marked by a relentless pursuit of innovation and adaptability. This forward-thinking approach is catapulting the company towards a new era of industrial excellence. With Flexxbotics at the helm, the future of manufacturing is not just about interconnected and efficient processes; it’s about embracing sustainability and forward-thinking practices that will define the new standards of industrial excellence.