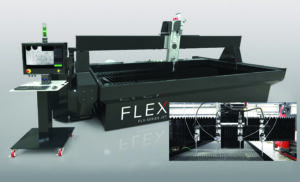

Flex Machine Tools, an American manufacturer and leading provider of machine tool solutions worldwide for metal fabrication operations and more, can configure a FlexJet waterjet system for unique cutting requirements. Customers can choose the pump, cutting head and machine size that is right for the application. FlexJet waterjet systems offer industry leading speed and rapid positioning, with head options ranging from conventional, 5-Axis and tilter to multi-head setups.

The multiple cutting head solutions offered for the FlexJet waterjet line provide increased efficiency by multiple heads cutting parts at one time, reducing overall cutting time and cost per part. The multi-head standard package options have two and four cutting heads, and can be expanded on.

Also, depending on the application, the multi-head solutions can be paired with higher horse power pumps so there is no performance loss at the individual cutting head. For consistent abrasive delivery, each head has its own dedicated mini hopper, and each head can be turned on and off independently so only those needed are engaged in cutting. An auto spacing feature makes adjusting the cutting head spacing fast and simple with 48″ maximum and 5.5″ minimum spacing between heads.

Also, depending on the application, the multi-head solutions can be paired with higher horse power pumps so there is no performance loss at the individual cutting head. For consistent abrasive delivery, each head has its own dedicated mini hopper, and each head can be turned on and off independently so only those needed are engaged in cutting. An auto spacing feature makes adjusting the cutting head spacing fast and simple with 48″ maximum and 5.5″ minimum spacing between heads.

FlexJet waterjets are designed to tackle intricate jobs effortlessly with a user-friendly design that prioritizes workflow, increases productivity, and delivers exceptional cutting power. Engineered and built in the USA, FlexJet waterjets are reliable for the most demanding cutting applications. Flex can customize waterjet solutions to match application requirements, and provide stellar service and 24/7 remote response. Flex service technicians are located throughout North America.