“Like all new entry-level machines from TRUMPF, the TruBend 1000 is precisely tailored to the needs of companies looking to break into metal bending,” says TRUMPF Inc. TruBend Product Manager Chris Wargo. “The machines are every bit as robust and reliable as our high-end models, but at a much lower price tag. We can now provide even more solutions to help companies grow and manufacture competitively.”

Easy entry into metal bending

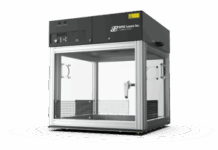

TruBend 1000 Series customers benefit from the latest digital technology and TRUMPF services. If any questions or issues arise, TRUMPF technicians can connect with the machine online and provide customers with remote support. The TruBend 1000 has features designed to meet the needs of companies getting started in metal bending. The press brake comes with the proven TRUMPF tooling clamp and is compatible with TRUMPF bending tools. In addition, users have access to a demo version of TRUMPF’s offline programming software TecZone Bend. This means the machine can be programmed from the office while in full operation, to increase productivity even more.

Perfect for simple parts and medium-to-large workpieces

The TruBend 1000 is suitable for all companies who manufacture simple and semi-complex parts in small to medium batch sizes. This model comes with the TRUMPF tool system and is suitable for small batch sizes, as tool changes can be done quickly. The press brake is attractive for smaller companies or contract manufacturers operating in single shifts. The first machine available in the series has a capacity of 165 tons and 10.17 feet of bending length. Further machine sizes and bending lengths will follow.

About TRUMPF

TRUMPF is a high-tech company offering manufacturing solutions in the fields of machine tools and laser technology. It drives digital connectivity in manufacturing through consulting, platform products and software. TRUMPF is one of the technology and market leaders in highly versatile machine tools for sheet metal processing and in the field of industrial lasers. In 2023/24, TRUMPF employed approximately 19,000 people and generated sales of about $5.58 billion USD. With about 90 companies, the TRUMPF Group is represented in nearly every European country as well as in North America, South America and Asia. The company has production facilities in Germany, France, the United Kingdom, Italy, Austria, Switzerland, Poland, the Czech Republic, the United States, Mexico and China.