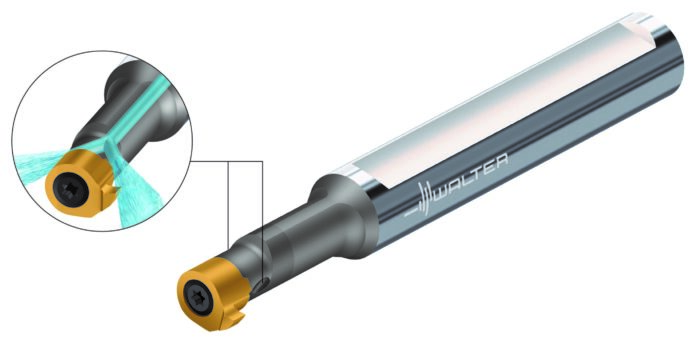

New WE “Exchangeable” heads and W3270/W3271 boring bars from Walter enable repeatable high-quality machining to minimize the rejection rate and maximize tool life due to the precision ground and sharp cutting edge. A large standard range is available, as well as specials with a short delivery time.

The WE head is for internal machining from 0.276 in. (7 mm) in diameter and axial grooving from 0.472 in (12 mm) in diameter. The WE positive engagement with three contact surfaces provides a high level of process reliability, stability and accuracy. The tool maximizes flexibility due to the ability to replace the WE head in the same toolholder (from a Dmin of 0.276 in.).

The W3270/W3271 boring bars are available in 12-16-mm and 0.5-0.625 in. with clamping surface in steel and carbide. For universal applicability, the coolant outlet is on both sides for the W3270 radial boring bars. Rake face cooling and an additional flushing hole enable a high-volume flow. The W3271 axial boring bars are handed (right hand/left hand) and have the coolant outlet either on the right- or left-hand side of the bar optimized for the most efficient cooling.

The inserts are made of grade WSM23X or WSM13X. The WSM23X is primarily for cutting steel (ISO P25), stainless steel (ISO M25) and materials with difficult machining properties (ISO S25). The secondary application is cutting non-ferrous metals (ISO N25). The PVD grade with a multiple-layer titanium aluminum nitride (TiAlN) coating and titanium nitride (TiN) top layer is for parting off/grooving and turning with a moderate to low cutting speed (vc) and axial depth of cut (ap).

The WSM13X has a higher wear resistance than WSM23X for stable machining conditions. The primary applications for the WSM13X are cutting steel (ISO P15), stainless steel (ISO M15), material with difficult machining properties (ISO S15) and non-ferrous metals (ISO N15). The PVD grade features a multiple-layer TiAlN coating.

The exchangeable head types include copy turning (profiling) (WE-C), thread turning (WE-I), axial grooving (WE-AC), axial grooving (WE-A), reverse turning (WE-B), forward turning (WE-T), forward turning with a ground chip breaker (WE-TX), and internal grooving (WE-G).

About Walter

Walter, a global leader in the metalworking industry for over 100 years, offers a wide range of precision tools for milling, turning, drilling and threading applications. The company helps customers in the aviation and aerospace industries, automotive, energy, and general metalworking industry improve process reliability and increase productivity. As an innovative partner capable of creating digital process solutions for optimal efficiency, Walter is pioneering Industry 4.0 throughout the machining industry. With Regional Headquarters in Greer, SC, Walter markets its competence brands Walter, Walter Titex, Walter Prototyp and Walter Multiply through a network of channel partners and field engineers across the USA, Canada, Mexico and Brazil. www.walter-tools.com/us.